Editorial

Investigation of materials at the nanoscale is leading to fantastic findings, material enhancements & new products every day. Small Angle X-ray Scattering or SAXS is emerging as a major technique for characterizing materials. With ‘Exploring the very small’ we would like to share our enthusiasm for this powerful technique and hope to gather a growing community of users and scientists curious about it.

‘Exploring the very small’, will help you to keep up to date with the latest news on nanoscale characterization, provide regular insights on what can be done today with Small and Wide Angle X-ray Scattering, and feature new product developments & innovations in SAXS instrumentation.

We hope you will enjoy ‘Exploring the very small’.

Xenocs Editorial Team

Today at the nanoscale

We are proud to highlight some of the recent publications from our customers emphazising the usage of the SAXS/WAXS technique for characterising nanostructured materials in the lab. The following selection illustrates the variety of fields of research for which SAXS/WAXS is used.

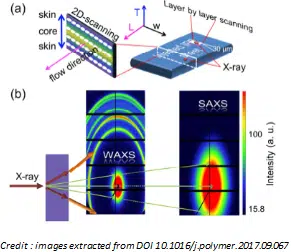

Isotactic polypropylene samples filled with anisotropic TiO2 Nanoparticles prepared by injection molding were characterized by spatially resolved 2D SAXS/WAXS measurements on a Xeuss 2.0 system at INM Leibniz Institute for New Materials. Orientation of molecules, of crystalline lamellae and of filler particles were thus analyzed as well as their position dependence in the film. SAXS/WAXS combined analysis contributed to propose a scenario for understanding nanoparticles templating process for crystallization during injection molding leading to improved elastic modulus of the corresponding nanocomposites.

Original article : P. Zhang P, T. Kraus; Polymer (2017); DOI: 10.1016/j.polymer.2017.09.067.

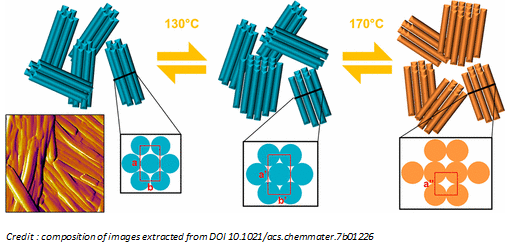

Original article : Y. Abe & al.; Chem. Mater., 2017, 29 (18), pp 7686-7696; DOI: 10.1021/acs.chemmater.7b01226

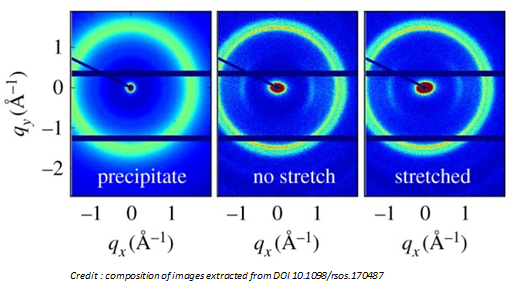

Dissolution state of microcrystalline cellulose was studied in an ionic liquid solvent (TBAH) by turbidity measurements and SAXS characterization at Lund University in Sweden. Different regimes were thus defined (stable, metastable, unstable) depending on solvent concentration and crystalline polymorph. Polymorph state of regenerated cellulose was further in-situstudied with WAXS analysis using a new type of in-house cellulose injection scheme which could facilitate the investigation and control of precipitation of cellulose into fibres.

Original article : M. Gubitosi & al.; R Soc Open Sci 2017 Aug; 4(8): 170487; DOI: 10.1098/rsos.170487

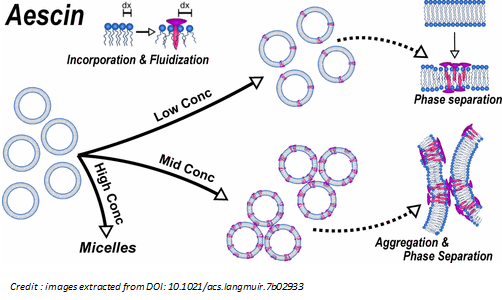

Sreij & al studied the mixing properties of aescin, a natural surfactant with DMPC a phospholipid typically used to mimick cell membranes. Three different concentration regimes were evidenced using Differential Scanning Calorimetry (DSC) and Photon Correlation Spectroscopy (PCS) measurements combined with SAXS and WAXS measurements performed on a Xeuss 2.0 system at Bielefeld University. WAXS was used to characterize head to head correlation distance (dx) as a function of temperature, and allow direct observation of the phase transition for phospholipid vesicles. At high concentration of aescin, SAXS allows to describe the self-assembly scenario dominated by aescin based micelle-like aggregates.

Original article : R. Sreij & al; Langmuir, 2017, 33 (43), pp 12351-12361; DOI: 10.1021/acs.langmuir.7b02933

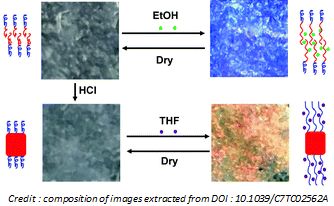

Scientists from South Carolina University achieved synthetization of photonic crystals through block copolymer self-assembly with two different approaches : self-assembly from a block copolymer with modest molecular weight and block copolymer grafted silica nanoplatelets. Phase separation of both type of polymers was characterized with high resolution SAXS measurements evidencing the large d-spacing, and domain thickness changes depending on process conditions and correlated with color changes.

Original article : Y. Huang & al.; J. Mater. Chem. C, 2017,5, 9873-9878; DOI: 10.1039/C7TC02562A

Any news which has raised your interest you want to share ? Please send it to us !

Characterization focus

Accurate nanoparticles size distribution from SAXS measurements in the lab

The wide use of nanoparticles and the growing attention to regulatory provisions for nanomaterials in general induce a large interest for nanoparticle size characterization. One major challenge is related to the metrological approach as addressed in the published ISO standard[1]. SAXS is now known as a reliable method to investigate nanoparticle size distribution[2]. This article shows the capability to run reliable SAXS measurements in the lab on large size nanoparticles (> 100 nm) and to define with accuracy the size distribution even for a bi-modal population with close size values, using the Expectation Maximization (EM) method for the analysis.

The EM framework[3] applied to the SAXS on spherical nanoparticles provides the solution for the particle size distribution offering the highest level of agreement, from the statistical point of view, with the experimental data[4]. No assumption is made on the mathematical form of the distribution (form-free), which is one great advantage compared to other calculation procedures.

SAXS measurements were performed using Xenocs instruments. Data processing was performed using Xenocs data reduction software (Foxtrot) that allows easy reduction from 2D to 1D data and buffer contribution subtraction in absolute intensity units. Then data were directly analyzed using the EM method.

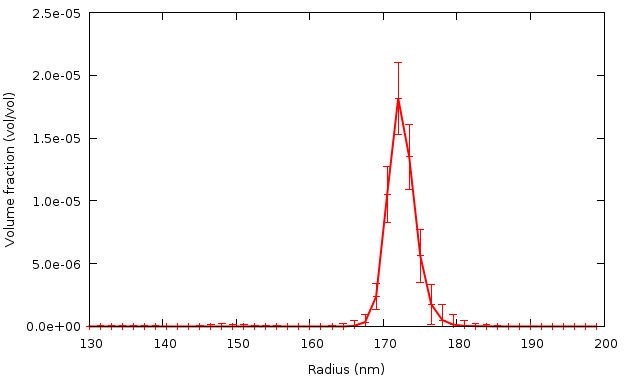

First sample consists of an aqueous solution of large SiO2 particles[5] with a concentration of 1 mg/L. Use of the EM method to fit the SAXS curve allows the determination of particle size distribution (Figure 1). The obtained size distribution curve is consistent with the description as given by the provider[5].

Figure 1. Volume-weighted particle size distribution of a diluted solution of SiO2 nanoparticles in water (c = 1 mg/L) from 1D SAXS data fitting using the EM method. Nominal diameter = 340 nm. SAXS measurements run on a Xeuss HR at Sassenage, France.

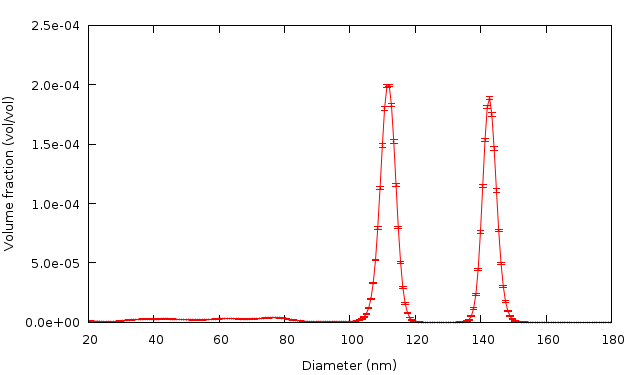

A bi-modal mixture was prepared from SiO2 aqueous dispersions from Microparticles GmbH :

- Sample A: nominal size 115 nm,

- Sample B: nominal size 148 nm.

From EM analysis, two distinct peaks of the size distribution are shown at 115 and 148 nm (Figure 2). The resulting volume-weighted size distribution is consistent with those of the individual samples.

This result shows that SAXS in the lab using a Xenocs system and the EM method allows to detect a bi-modal nanoparticle suspension with high precision, even with mixture of particles being close in size.

Figure 2. Volume-weighted particle size distribution of a bi-modal SiO2 particle aqueous dispersion from 1D SAXS data fitting using the EM method. Nominal diameters = 115 and 148 nm. SAXS measurements run on a Nano-inXider at Sassenage, France.

[1] Nanotechnologies — Vocabulary — Part 2: Nano-objects ISO/TS 80004-2:2015

[2] Particle size analysis – Small angle X-ray scattering method ISO 17867:2015

[3] M. Bertero and P. Boccacci, Introduction to inverse problems in imaging, Institute of Physics, Bristol, UK (1998)

[4] F. Benvenuto, H. Haddar and B. Lantz, SIAM J. Appl. Math., 2016, 76(1), 276-292

[5] Sample courtesy of Karlsruhe Institute of Technology, Germany.

They are exploring the very small

Studying solutions, gels, powders and thin films with the Nano-inXider

Interview with Professor Lam Yeng Ming, School of Materials Science & Engineering, College of Engineering, Nanyang Technological University, Singapore

The Nano-inXider SAXS/WAXS instrument from Xenocs was installed in November 2016 at the Nanyang Technological University, Singapore. Interview with Professor Lam Yeng Ming after 14 months of use of the equipment.

Could you please give a bit of background on the laboratory where the instrument is installed?

Prof. Lam: The instrument is installed in FACTS, which is a University characterization facility in NTU (Singapore) that focuses on in-depth materials characterization using X-rays and electron-microscopy analysis and training. We are dedicated to support research activity in NTU and other academic/research institutions in Singapore.

Could you please give a brief introduction to your current research work and how SAXS information is useful for your area of research?

Prof. Lam: As a university central facility, we cover a wide variety of materials relating to a huge spectrum of research. So far SAXS information provides morphological information for nanomaterials and thin films. SAXS also helps in the elucidation of phase and phase transformation in polymers, surfactants and other biomolecules. Our facility also has other X-ray characterization and electron microscopes. SAXS complements the thin film and powder X-ray diffractometers as it covers the low angle regime. SAXS provides a more global information compared to the Electron Microscopy techniques.

How many users are working on the Nano-inXider and for which main applications?

Prof. Lam: As of now, there are at least 8 people actively using the machine, and the number may change due to the nature of facility. We look at different materials – organic, inorganic, hybrid. They come in different forms solutions, gels, powders and thin films. The applications range from consumer care, biomedical to energy related.

Could you tell us why you chose the Nano-inXider from Xenocs and if it meets your expectations?

Prof. Lam: The Nano-inXider is the tool we needed to complement our existing characterization facilities. It is very easy to use and versatile. The ability to collect the WAXS data simultaneously with the SAXS data is certainly an advantage. The modular features of the instrument allow us to study a wide range of samples, which is a real advantage for multiple users coming with various needs.

What do you think of Xenocs support & services?

Prof. Lam: The support we received so far has been very positive. The online support team is very prompt and responsive.

Contact: [email protected]

Link to faculty profile

Product highlight

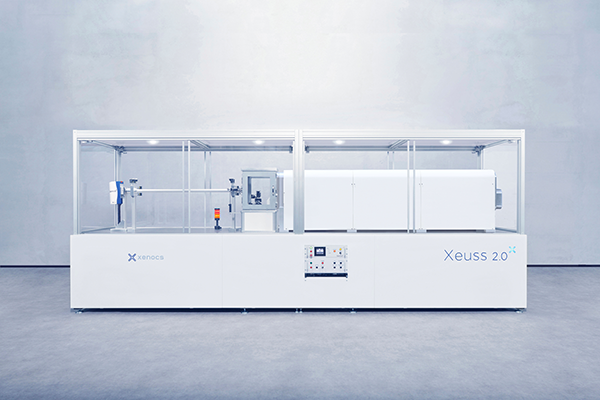

Xeuss 2.0 Q-Xoom: the agile detector

The Q-Xoom is the latest addition to the Xeuss 2.0 family and a result of the Xenocs-Saxslab collaboration. The Q-Xoom moving detector concept allows the fully automated optimization of instrument configuration to the user’s measurement and experiment. It was originally developed on synchrotron beamlines and introduced in the laboratory by Saxslab.

The motorized adjustment of sample to detector distance gives the user the option to optimize detector coverage, resolution and Q-min, effectively moving from WAXS over MAXS to SAXS settings. It is also easy to acquire data with different settings in record time, including through remote operation.

With the detector in vacuum and with no windows in the beam-path, noise is reduced, and the dynamic range of the instrument is increased, covering about 10 orders of magnitude in signal.

The detector position is recorded yielding accurate establishment of the Q-range. With the sample being stationary, the beam-dimensions on the sample are constant and the user is sure to probe the same part of the sample for different detector settings. The stationary sample also preserves the Xeuss 2.0 capability for large sample environments and sample-in-air operation.

The Q-Xoom moving detector option is a milestone in SAXS instrument flexibility, performance and productivity.

Xenocs news

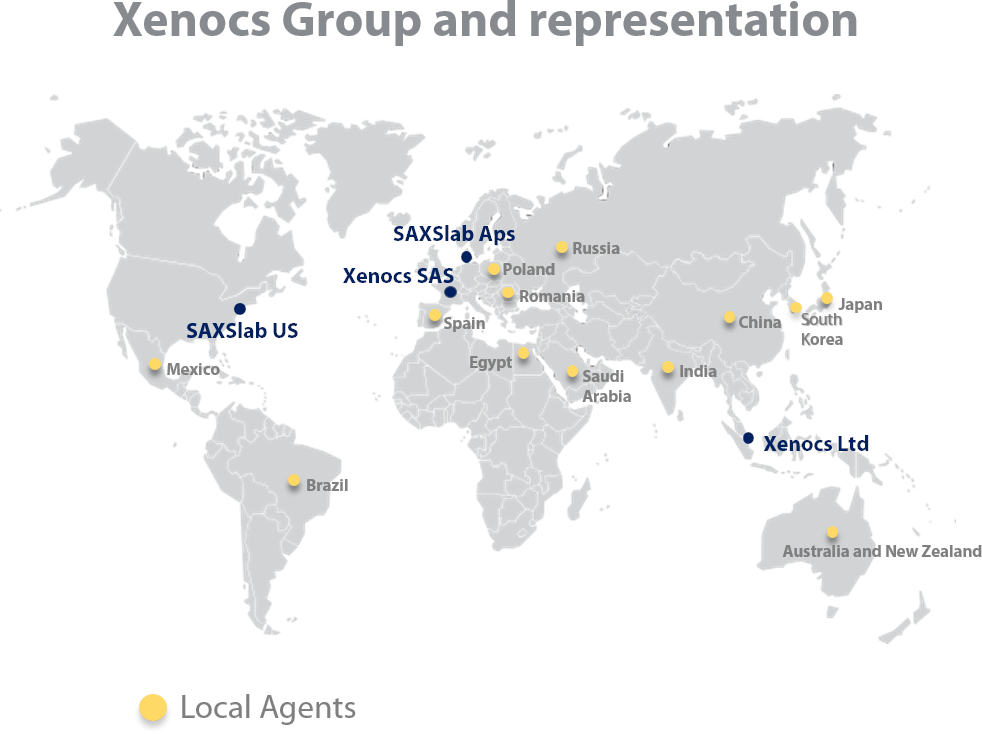

Xenocs acquired SAXSLAB. 12 months later...

The acquisition of SAXSLAB one year ago was a milestone in Xenocs’ development. Twelve months later, let’s see what has changed for Xenocs and its customers…

With the acquisition of SAXSLAB twelve months ago, Xenocs has strengthened its market presence worldwide, especially in North America. With SAXSLAB US joining the Xenocs group, the strong team set up in Amherst, Massachusetts has vaulted Xenocs into the most prestigious x-ray scattering institutions in the US.

“We are thrilled to be part of Xenocs group – it’s hard for me to be more enthusiastic.”, SAXSLAB US Sales Director Dr. Scott Barton states. “With our combined expertise and technologies, we can demonstrably offer our customers the best solutions for nano- and meso-characterization of materials by SAXS and WAXS. I am extremely proud that this year, U Minnesota, U Southern Mississippi, Iowa State, U Chicago, and U Texas Austin were among those who chose Xenocs products for high performance SAXS/WAXS solutions”.

This strong presence in the US has enabled Xenocs to dedicate resources to develop their presence in other markets, such as Asia and the Middle East. The company’s target markets have also been extended from academic and governmental laboratories to corporate research labs.

“We are now offering our solutions not only to universities but also to industrials”, Xenocs Managing Director Frédéric Bossan explains. “In this context, the sales of a Nano-inXider SAXS/WAXS instrument to Arkema and to Aramco this year are significant of the growing need of the industry for having easy access in the lab, to information at the nanoscale with SAXS and WAXS.”

The union of forces with SAXSLAB and the synergies in the two companies’ technologies have led Xenocs to launch two new products this year: the Xeuss 2.0 with Q-Xoom and the BioXolver for structural biology.

“At Xenocs we have always been dedicated to putting our skills and technologies in the development of solutions which contribute to better science. With our extended product range, we are now able to answer the various needs of our customers for nano characterization solutions based on SAXS & WAXS”, Frédéric Bossan says. “It’s been twelve very exciting months since the acquisition, full of promises for the coming years!”