Surface structure and patterns

Surface structure and patterns,

what is measured?

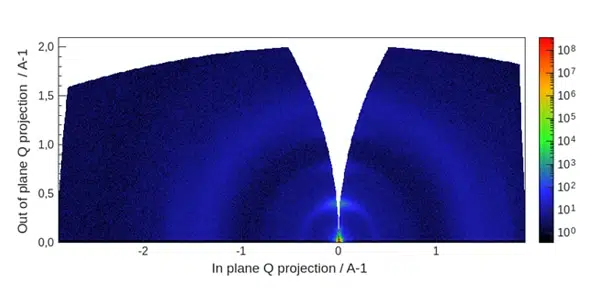

One measures the long range order parameters of a nano-structured surface (GISAXS) or its atomic scale structure (GIWAXS).

The 2D scattering data gives an indication of the presence of such ordering while 1D data plotting along a given direction can give information about structure characteristic dimensions or orientation.

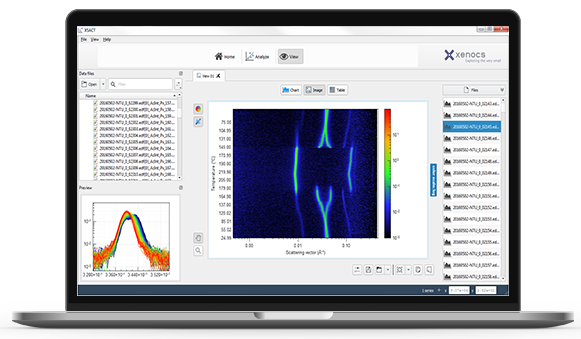

Figure 1. Wedge corrected grazing incidence wide angle x-ray scattering data acquired on a P3HT:PCBM thin film on a silicon substrate. The raw data is transformed with XSACT software such as to illustrate the in-plane and out-of-plane scattering patterns.

Samples

Typical samples for this measurement are polymers, inorganic materials of the following structure:

-

Nanopatterned surfaces

-

Nanostructured or porous thin films

-

Nanolayered materials (stackings)

Examples of GISAXS/ GIWAXS applications in polymer science:

- Müller‐Buschbaum, P. “The Active Layer Morphology of Organic Solar Cells Probed with Grazing Incidence Scattering Techniques”. Advanced Materials, 26, 7692–7709 (2014).

- Sung, S.J., et al. “ Enhanced gas barrier property of stacking-controlled reduced graphene oxide films for encapsulation of polymer solar cells “. Carbon, vol 150, pp. 275-283 (2019).

- Guliyeva, A. et al. ” Transition Pathway between Gyroid and Cylindrical Morphology in Linear Triblock Terpolymer Thin Films “. Macromolecules, 52, 17, 6641–6648 (2019).

Examples of GISAXS data analysis for inorganic thin films:

- Hohn, N. et al. “Amphiphilic diblock copolymer-mediated structure control in nanoporous germanium-based thin films.” Nanoscale, 11, 2048–2055 (2019).

- Reid, B. et al. “Photocatalytic Template Removal by Non-Ozone-Generating UV Irradiation for the Fabrication of Well-Defined Mesoporous Inorganic Coatings.” ACS Appl. Mater. Interfaces 11, 19308–19314 (2019).

Methods & standards

Why use SAXS for surface structure and patterns determination?

Advantages of SAXS for surface structure and patterns determination:

-

Statistical relevance : get information from several layers or surface

-

Adapted for conducting or non conducting materials

-

Non destructive method

-

Compatible with in-situ dynamic experiments (temperature, drying)

Products

All these measurements are possible directly in your lab.

Xeuss Pro

The Ultimate Solution for Nanoscale Characterization using SAXS/WAXS/GISAXS/USAXS/Imaging