Polymer research

Characterization at the nanoscale can help you find answers.

With X-ray scattering in your lab, you can for example:

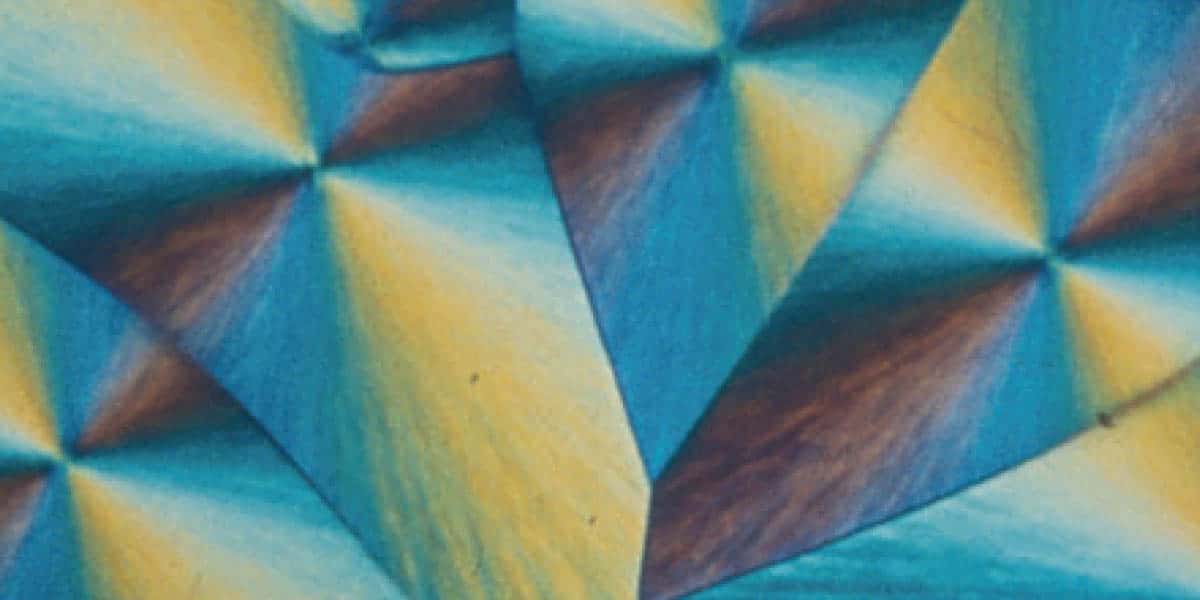

- Determine the phase of self-assembled block-copolymers or liquid crystalline polymers

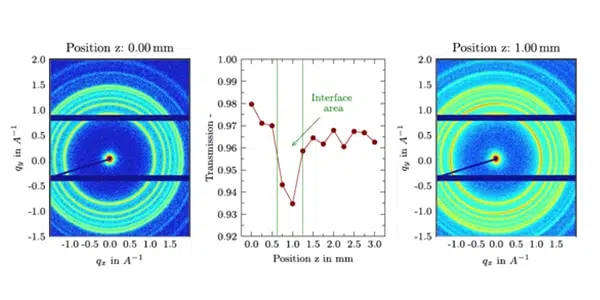

- Reveal spatially resolved structural variations due to processing such as injection molding

- Test the tensile properties of plastics or follow the degree of crystallinity during controlled cooling

- Investigate thickness and morphology of polymer and composite films

- Characterize the size, shape and distribution of rubber-fillers or polymeric colloids and micelles in dispersion

Using wide-angle X-ray scattering to measure low-level crystallinity

Determination of crystalline fractions in a polyolefin down to 0.3% during a kinetic experiment using integrated temperature control.

With SAXS and WAXS you can study polymer samples in situ

Internal structure, interfaces, effect of stress and strain, temperature or humidity…

What are you looking at?

Want to learn more on SAXS for polymer research?

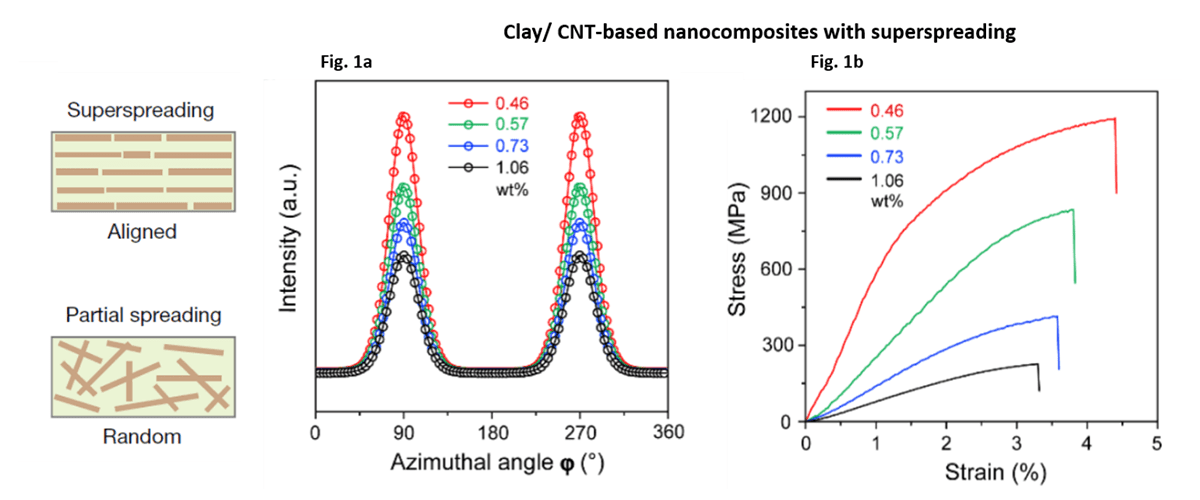

Analysing polymer nanocomposites with X-ray scattering

Nanocomposites are a class of high-performance materials which are attracting attention in various industries such as for example the automotive industry […]

SAXS/WAXS results help elucidate structure-funtion relationships in foams

Foams – gas trapped in solids or liquids – are common materials, found all around us. Liquid foams can be found in cosmetic formulations, home care products and food, whereas solid foams find use in […]

Polymer phase transformation

Simultaneous SAXS/WAXS measurements of a semi-crystalline polymer during thermal processing enables determination of route for phase transformation.

Silk fiber nanostructure investigation

SAXS/WAXS measurements enable the determination of the characteristic dimensions and the semi-crystalline structure of Bombyx mori cocoon silk fibers.

Determination of polymer crystallinity

The level of crystallinity of a polyolefin was determined during a kinetic experiment using the Xeuss SAXS/WAXS system in combination with an integrated temperature control stage, the Linkam HFSX350.

Some of our customers

using X-ray scattering for their study of polymers

“ In electron microscopy, you must prepare your sample by slicing and cutting the sample and therefore it gives no chance to study the properties in situ, during for example thermal treatment or mechanical testing . But with SAXS you can do it.”

Prof. Yongfeng Men, CIAC, Chinese Academy of Science

Customer publications

Discover how scientists use Xenocs instruments for their research & publications

Products

Discover our products relevant to polymer research.

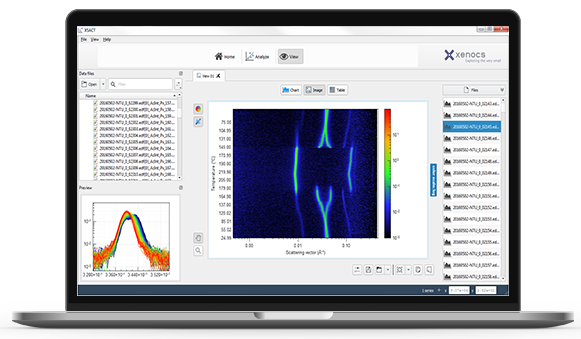

Xeuss Pro

The Ultimate Solution for Nanoscale Characterization using SAXS/WAXS/GISAXS/USAXS/Imaging