Editorial

We are thrilled to announce the launch of ‘Exploring the very small’, our Small Angle X-ray Scattering Newsletter!

Investigation of materials at the nanoscale is leading to fantastic findings, material enhancements & new products every day. Small Angle X-ray Scattering or SAXS is emerging as a major technique for characterizing materials. With ‘Exploring the very small’ we would like to share our enthusiasm for this powerful technique and hope to gather a growing community of users and scientists curious about it.

‘Exploring the very small”, will help you to keep up to date with the latest news on nanoscale characterization, provide regular insights on what can be done today with Small and Wide Angle X-ray Scattering, and feature new product developments & innovations in SAXS instrumentation.

We hope you will enjoy ‘Exploring the very small’.

Xenocs Editorial Team

Today at the nanoscale

Understanding and controlling the structure of materials at the nanoscale is critical for the development of advanced material. In this section, we share with you some recent scientific articles on the use of SAXS characterization, that through their diversity highlight the growing impact of this technique in today’s research.

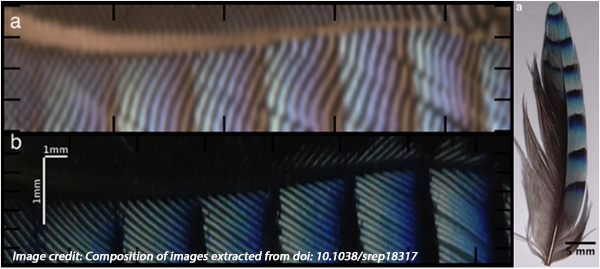

Let us start with a mystery of nature explained by scientists from the University of Sheffield who characterized Eurasian Jay’s colorful feathers at the ESRF ID2 SAXS/WAXS beamline. The study shows that the alternating colors of the feathers is due to the spatial modulation of their nanostructure. This could be a great source of inspiration for the paint industry to obtain adjustable colors that do not fade.

Original article : Parnell, A. J. et al. ; Scientific Reports 5, 18317; doi: 10.1038/srep18317.

Researchers at ORNL have developed a 50 percent renewable thermoplastic polymer called ABL (acrylonitrile-butadiene-lignin) as an alternative to ABS by substituting styrene with lignin. The lignin is dispersed in a network of sheets throughout the rubber matrix. SAXS was used at ORNL to characterize the network of lignin clusters within the rubber matrix on this green renewable polymer which is ten times tougher than ABS.

Original article : Tran et al. ; Advanced functional materials, vol 26, Issue 16 ; doi: 10.1002/adfm.201504990

Scientists at INRA Montpellier investigated a new type of gelation process of gluten proteins. These gels show enhanced mechanical properties compared to hydrated gluten. SAXS and SANS (Small Angle Neutron Scattering) measurements – performed respectively at ESRF, Laboratoire Charles Coulomb de Montpellier and Heinz Maier-Leibnitz Zentrum – were combined to study the percolation models of the new type of gels. This result opens new perspectives for improving the production process of plant based proteins for food products.

Original article : Dahesh et al. ; Food Hydrocolloids, 01/2016, 52:1-10

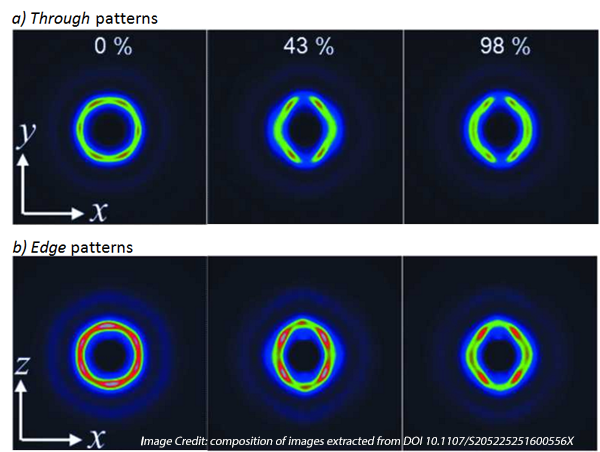

A team of scientists from Kyushu University and University of California in Irvine investigated the mechanical deformation of colloidal crystal films made of polymer grafted nanoparticles of silica (185 nm size) using in-situ USAXS measurements during uniaxial stretching. Experiments were performed at SPRING 8. USAXS helped to understand that nanoparticles reorientation under deformation induces structural changes with distortion and reorientation of some crystallographic planes towards the films surface. This could impact the structural color of the films.

Original article : Ishige et al. ; IUCrJ, 05/2016, vol 3, Part 3 ; doi:10:1107/S205225251600556X

Scientists from LPS Orsay and Lions CEA Saclay, France, have produced a solution of imogolite nanotubes displaying a highly stable columnar phase despite low volume fractions (as low as 0.2%). This phase with such high dilutions is easily aligned under alternating current electric field. Characterization was performed at the SAXS SWING beamline in SOLEIL. This result opens new perspectives for nanocomposite materials with nanotube filler in photonic applications.

Original article : Paineau et al., Nature Communications 7, 10271, doi:10.1038/ncomms10271

Any news which has raised your interest you want to share ? Please send it to us !

Characterization focus

Crystallinity and size of nanoparticles can be studied with combined SAXS/WAXS technique

Controlling the size of nanoparticles as well as their crystalline phase is critical to achieve or stabilize the final properties of many functionalized materials.

SAXS is gaining significant interest for assessing nanoparticles size distribution as measurement can be performed on a large probed volume (about 1 mm3) offering statistical information in a very accurate way with minimum sample preparation. Nanoparticles can thus be characterized not only diluted in solutions, but also within a polymer matrix or as a dry powder. The technique is for example referenced in the 2012 JRC report of the European Commission about the definition of Nanomaterials, and new standard for nanoparticles sizing has been published recently – Ref 17867:2015 (Particle size analysis-Small Angle X-ray Scattering).

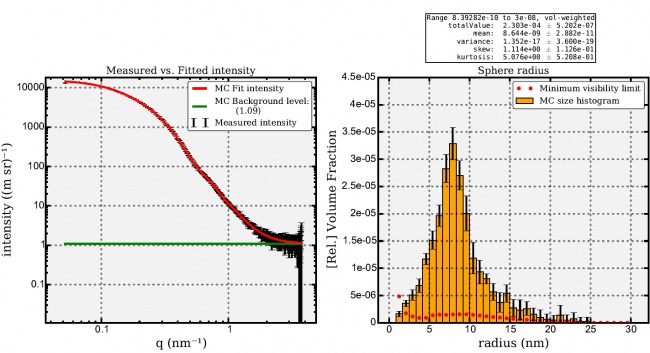

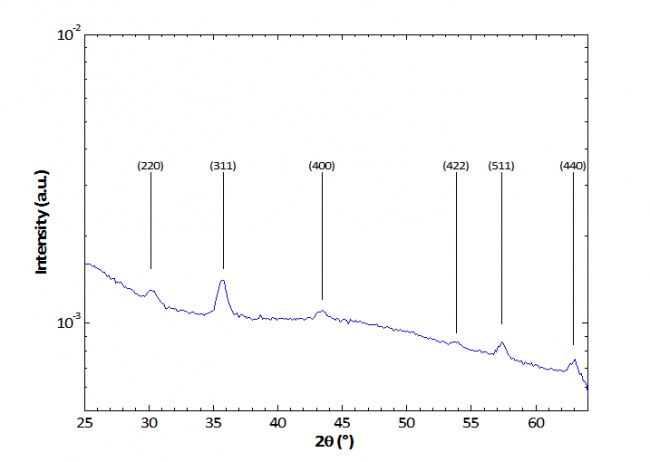

We show below an example of Fe3O4 nanoparticles characterization. The size of particles and the nature of the crystalline phase can strongly impact the very specific properties of ferrofluids. Characterization of size distribution and crystalline phase on a highly diluted solution of magnetite nanoparticles in toluene (with oleic acid as a stabilizer) was obtained through simultaneously measurement of the small and wide angle x-ray scattering properties.

The SAXS signal of the magnetite core was fitted with a spherical shape. SAXS analysis showed a mean radius of 8.64 nm. Size distribution could be deduced through data fitting (Figure 1).

Figure 1. McSAS 1 graphical output showing the best fit on SAXS data of magnetite diluted solution obtained using the Monte Carlo method (left) and the volume-weighted size distribution associated with the MC fit (right). The distribution shows a mean dimension of 8.64 nm and a width (standard deviation, σ=√(variance)) of 3.68 nm.

At the same time, the Fe3O4 crystalline phase could be confirmed through WAXS analysis as displayed in Figure 2.

Figure 2. WAXS profile from magnetite diluted solution and Fe3O4 crystalline phase identification 2 for Cu radiation.

The experimental results were obtained using the Nano-inXider SAXS/WAXS system from Xenocs.

Running simultaneous SAXS and WAXS measurements increases the measurement throughput, and enables the simultaneous study of structure & crystalline phases under the same in-situ variable experimental conditions, avoiding misleading interpretations due to hysteresis effects.

Widely used in R&D, the SAXS/WAXS technique is a non destructive method complementary to microscopy and light scattering. New developments in instrumentation, software and methods bring new opportunities for use in process analysis and quality control.

1Pauw, B. R., Pedersen, J. S., Tardif, S., Takata, M. & Iversen, B. B. (2013). J. Appl. Cryst. 46, 365–371.

2Standard structure of magnetite Fe3O4 – JCPDS card No. 74-0748

They are exploring the very small

Using SAXS/WAXS in our lab to study catalysts

Interview with Prof. Dr Sérgio Ribeiro Teixeira, Prof. Dr. Fernanda Poletto, Prof. Dr. Larissa Capeletti and Prof. Dr. Fabiano Bernardi, CNANO, UFRGS, Brazil

Focusing their research on catalysis and photocatalysis, the L3FNano laboratory at the Institute of Physics of the Federal University of Rio Grande do Sul in Porto Alegre, studies metal oxides semiconductors for hydrogen production by water splitting and the elucidation of catalytic events at the atomic level.

Several characterization techniques such as X-Ray diffraction, XPS, XAS, TEM, SEM, SAXS, RBS, BET and electrochemical measurements are used by the laboratory to study their samples. Small-Angle X-ray scattering (SAXS) is one of the most frequently used.

“We use nanostructured systems like metal nanoparticles as co-catalysts on the surface of nanostructured metal oxides semiconductors made by several different techniques. Our catalysts are commonly a combination of metal oxide semiconductors with metal nanoparticles co-catalysts. We aim to understand the shape and size of these catalysts and the correlation with other advanced properties. Because SAXS is a non destructive method, with limited sample preparation, giving information on a statistically relevant sample volume, it is a very powerful technique to study catalysts”, Prof. S.R.Teixeira explains.

In 2015, the laboratory acquired a Nano-inXider SAXS/WAXS system from Xenocs. Before getting the instrument, the users had to ask for beam time at the Brazilian National Synchrotron Laboratory (LNLS) to perform SAXS measurements. With the installation of the Nano-inXider at the Center of Nanoscience and Nanotechnology CNANO-UFRGS, the users can now make high performance SAXS /WAXS measurements in-house.

Prof. S.R.Teixeira, F. Poletto, L. Capeletti, and F. Bernardi around the Nano-inXider.

“We looked for a SAXS/WAXS system for our CNANO to give us the flexibility to run our experiments at any time we needed to. Now that we have the Nano-inXider in the lab, we use it every day and ask for beam time at the LNLS only when necessary”, Prof. F. Bernardi explains.

“We chose the Nano-inXider SAXS/WAXS system from Xenocs because it is compact and well designed while having the most important characteristics for making high quality measurements: beam collimation, flux, anti-scattering apertures and high quality detection. The Nano-inXider is easily operated and can be used for both liquids & solids. We can run temperature dependent measurements, and SAXS and WAXS measurements at the same time. There is also a GISAXS stage for samples with organized surfaces”.

While only four researchers were effectively using the equipment when the system was first installed last October, the demand is increasing very fast and measurements are now performed every working day for a broader range of applications, such as drug delivery applications and the characterization of liquid crystals & catalytic nanoparticles.

Product highlight

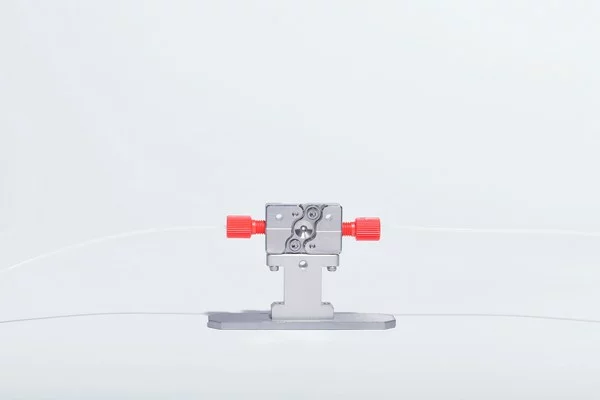

Low Noise Flow Cell - making the most of your samples

The capillary is the classic SAXS sample container for liquid samples. However, SAXS instruments have progressed to a performance level where a capillary may be a limiting factor for data-quality. In particular, the level of scattering from the capillary walls, the non-constant sample thickness across the x-ray beam and the use of different capillaries for sample and buffer measurements negatively affect the data-quality.

The Low Noise Flow Cell overcomes all of these difficulties:

- the scattering signature is 10x lower than that of a quartz capillary,

- the sample thickness variations are drastically reduced and

- the same sample container is used for both sample and buffer measurements making precise buffer signal subtractions possible.

How is it all possible?

The Low Noise Flow Cell uses SiN membrane windows. Manufactured and implemented correctly, the SiN windows can be very thin and have low scattering signature, while still being durable when used both in vacuum or at atmospheric pressure.

Xenocs Low Noise Flow Cell

The membrane windows provide a much more constant sample thickness across the x-ray beam and due to the Low Noise Flow Cell geometry, the sample thickness is well known.

The Low Noise Flow Cell stays in place while successive measurements of sample and buffer are done either with the use of a precision syringe or through the use of an autosampler with two 96-well trays. The autosampler is fully integrated with the instrument control software allowing for powerful macros and measurement sequence automation. Besides, the autosampler can do cleaning sequences and push a “train” of buffer-air-sample-air-buffer through the tubing to position the sample in the Low Noise Flow Cell.

A key point in the Low Noise Flow Cell design is that the seal is integrated with the SiN windows, allowing for minimal dead volume, easy exchange of windows and reproducible sample thickness. Moreover the tubing and connectors provide minimal dead volume which together with an optimized cavity geometry allow for the use of very small sample volumes.

Xenocs product engineers and application scientists have worked together to come up with this solution. Through innovation, iterations and tests, concepts were identified and matured with the benefits for our customers constantly in mind. The result is a tested and tried high performance solution that we believe will help our customers to achieve cutting edge research results.

Low Noise flow cell in the Nano-inXider instrument

Low Noise flow cell & autosampler in the Xeuss 2.0

Xenocs news

Getting Closer to Chinese end users – a focus on Xenocs' Sales and Service Center in China

Since the sale of its first SAXS system in Zhejiang Sci-Tech University in 2012, Xenocs has been actively developing its presence in China. With a customer base of 12 systems installed in only 4 years in some of the most prestigious universities in China, Xenocs is the leading supplier of SAXS/WAXS systems in the country.

In this context of rapid expansion, Xenocs has developed a very close collaboration with Beijing Unite Tech, to create a strong Sales and Service Center in China.

“China is a very demanding market, in which the standards of product quality and customer support are brought to a maximum. The collaboration we have developed over the years with Beijing Unite Tech is playing a key role in our development in China. Their approach of the market, expertise and dedication to customer satisfaction is a strong asset for us”, Xenocs Co-founder and Managing Director Frederic Bossan says.

Managed by Xiao Zhang and Hong Wang, Beijing Unite Tech offers a comprehensive sales and customer support service to Xenocs customers all over China. “As our installed customer base is expanding and interest for Xenocs solutions is growing every day, it was very important for us to get an adequate organization. Beijing Unite Tech is now a team of 10 people with strong expertise in sales and customer support. Initially located in Beijing, Beijing Unite Tech is now opening a new office in Hefei to better serve Xenocs customers in South China”, explains Xiao Zhang, Beijing Unite Tech CEO.

For more information about Xenocs in China & Beijing United Tech, please contact Xiao Zhang at [email protected], or visit our website in Chinese at www.xenocs.com