SAXS for Polymer Research

Polymer materials develop complex internal structures as they are synthesized, blended, stretched, cooled, or processed. Block copolymers form periodic nanodomains, while semicrystalline polymers grow lamellae within amorphous regions. At the same time, fillers distribute through the polymer matrix, tuning mechanical, optical, and barrier properties. Orientation can emerge under flow or tension, and thin films often develop gradients or ordered surface layers that differ from the bulk. These multiscale features determine how membranes separate, how packaging resists deformation, how coatings cure, and how composites perform. Therefore, to optimize these materials, researchers need tools that reveal how polymer morphology forms and evolves under realistic conditions.

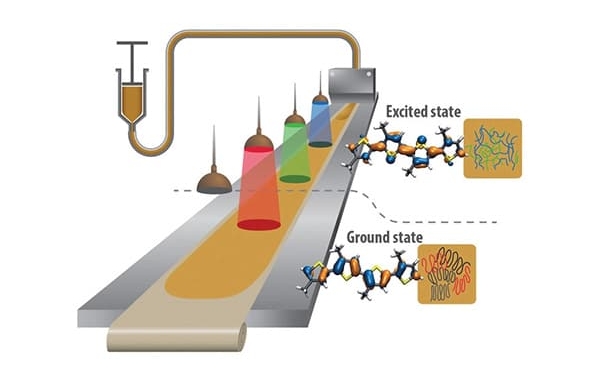

Laboratory Small and Wide Angle X-ray Scattering (SAXS and WAXS) and grazing-incidence techniques allow polymer structures to be examined under the exact conditions where they form or transform. In particular, researchers can observe polymer structures in situ during crystallization, solvent evaporation, order–disorder transitions, or thermal annealing. Measurements can also be done in operando during stretching, flow, or coating, revealing how lamellae thicken and block-copolymer domains reorganize. Additionally, these techniques show how orientation develops and how additives influence chain packing. This approach captures structural evolution in bulk materials and thin films without altering the sample. Consequently, it provides a direct link between processing history, nanoscale morphology, and the resulting mechanical, optical, or barrier properties.

Questions you can answer with SAXS for Polymer Research

How do PE, PP, or PA semicrystalline polymers develop lamellae during cooling, and how does the lamellar thickness influence mechanical strength and ductility?

What nanoscale morphology do PS-b-PMMA, PI-b-PS, or PLA-based block copolymers adopt under different annealing or solvent-casting conditions?

How does orientation in PET or biaxially stretched films evolve during tensile deformation, and how uniform is it across the film?

How do surface and bulk regions in thin polymer films differ in terms of ordering, density, or crystallinity after drying or annealing?

Are silica, carbon black, or nanoclay fillers well dispersed in an elastomer or thermoplastic matrix, or do they form aggregates or percolated networks?

How does the nanoscale architecture of polymeric membranes (e.g., UF, NF, or ion-exchange membranes) relate to pore size distribution and filtration or ion-transport performance?