SAXS for Nanoparticles and Colloids

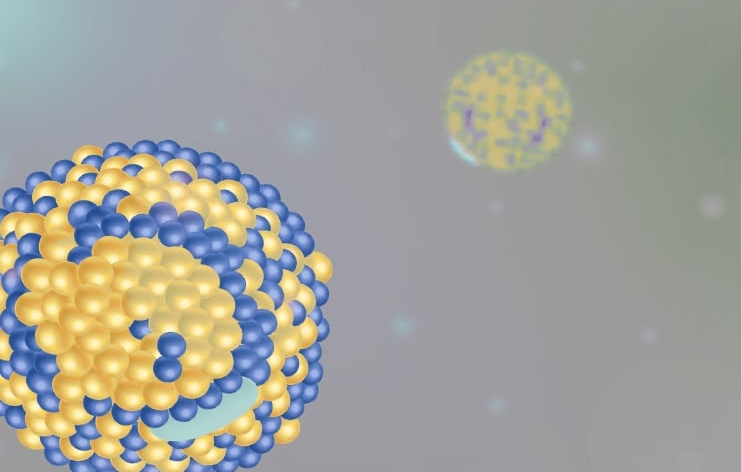

Nanoparticles derive their remarkable properties from structures that emerge at the nanometric scale. Their size, surface-to-volume ratio, internal architecture, and the way they are dispersed or assembled fundamentally dictate material properties. Even subtle changes at this lengthscale can shift performance dramatically. As materials evolve toward increasingly sophisticated architectures such as core–shell particles, hybrid nanostructures, and anisotropic colloids, precise control of nanoscale organization becomes essential for achieving reliable, tunable functionality.

Yet measuring these parameters across large particle populations, under native conditions and over relevant timescales, remains a significant challenge. Here, Small-Angle X-ray Scattering (SAXS) provides decisive value. SAXS delivers statistically robust, ensemble-averaged information on size distributions, shapes, internal contrasts, and interparticle correlations in solutions, powders, or solid matrices, without drying, staining, or disruptive sample preparation. Furthermore, modern modeling approaches enable extraction of polydispersity, core–shell parameters, aggregate structure, and structure factors that capture colloidal interactions. Time-resolved SAXS and USAXS further extend this capability to growth, self-assembly, and aggregation kinetics, revealing nucleation, sintering, or destabilization pathways under realistic temperature, solvent, or ionic conditions. Finally, SAXS offers a quantitative foundation for optimizing nanoparticle synthesis, stabilizing formulations, and linking nanoscale organization directly to macroscopic performance.

Questions you can answer with SAXS for Nanoparticles and Colloids

What is the size and shape distribution of my nanoparticles?

How stable is the system over time, are there signs of aggregation or clustering?

What are the self-assembly or growth pathways that the nanoparticles in my system follow during synthesis or processing?

Can I determine whether my silica or metal-oxide nanoparticles remain individually dispersed in solution, or if they form aggregates that alter performance?

What is the size distribution and lipid shell thickness of my lipid nanoparticles or micelles, and how stable are these structures under storage or processing conditions?

How does the size and stability of catalytic nanoparticles influence their performance under reaction conditions?