Watch the video about

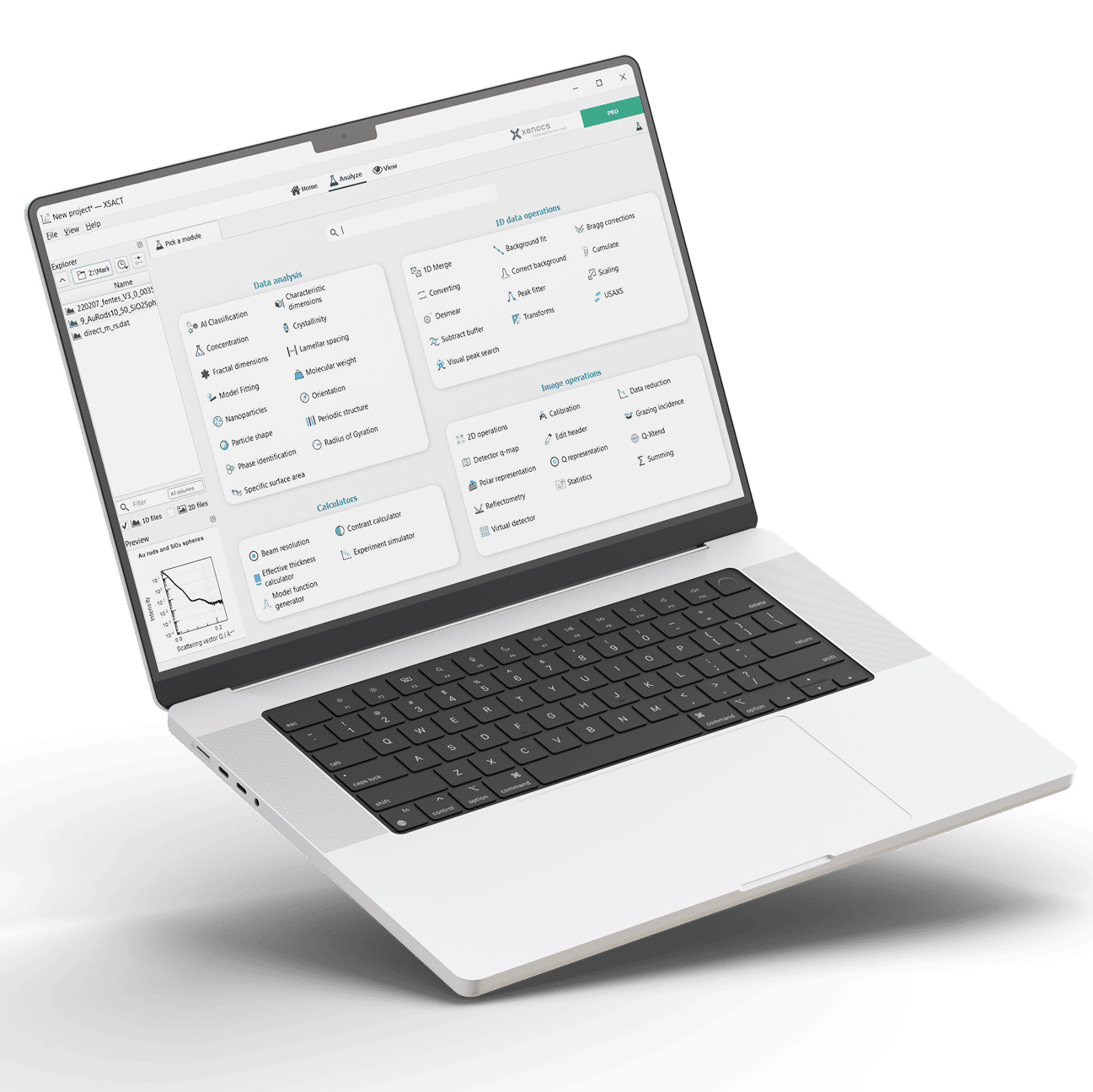

XSACT Pro SAXS

Software

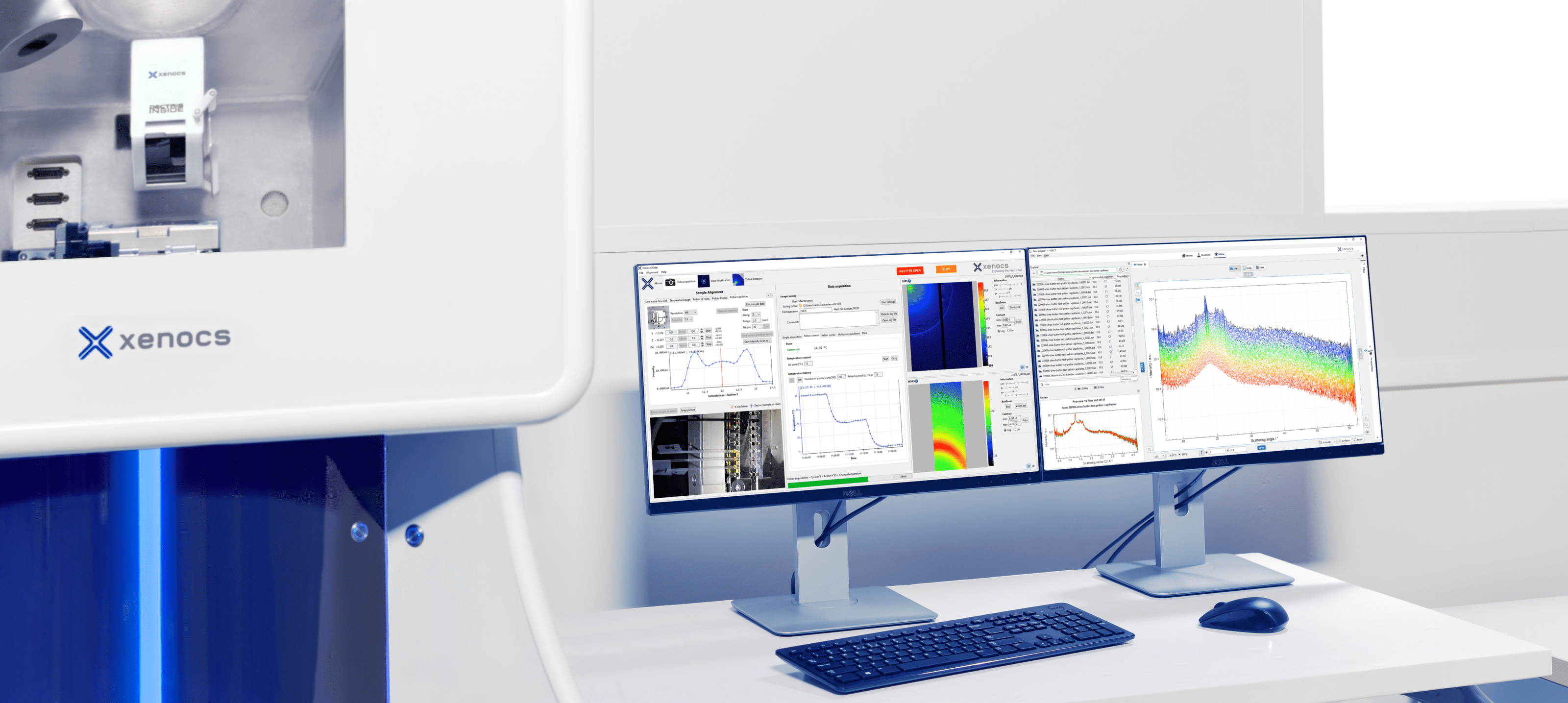

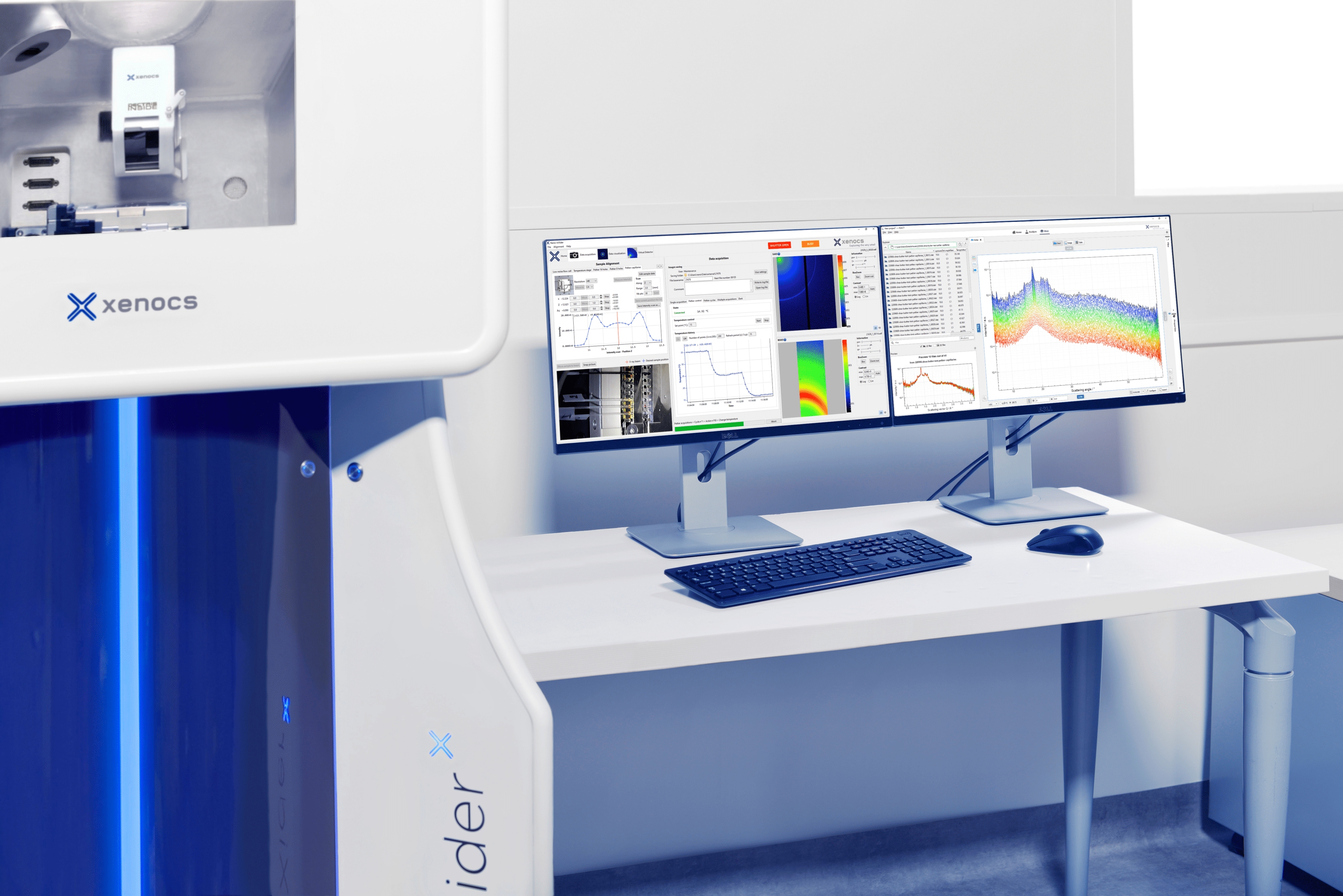

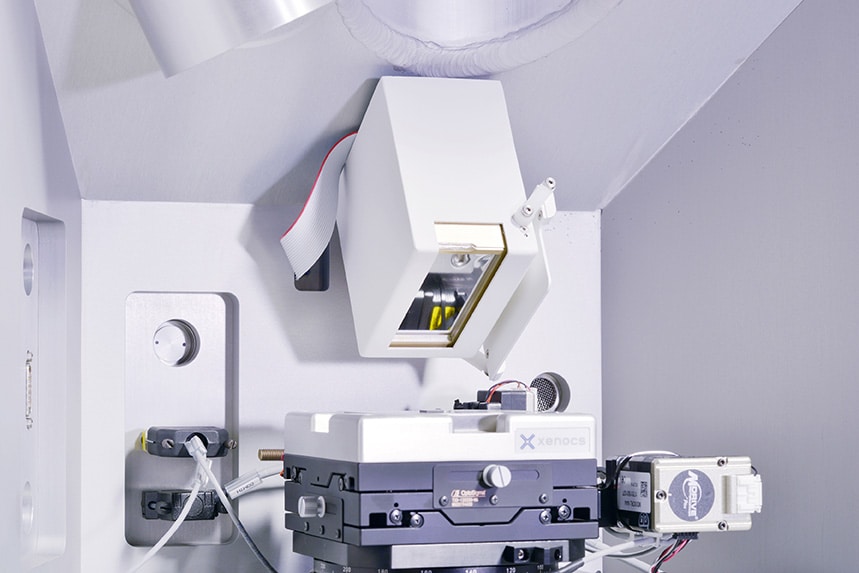

Nano-inXider: Smart nanoscale characterization with ease of use and high performance in a compact, intelligent design

The Nano-inXider SAXS/WAXS instrument for nanoscale characterization delivers fast, reliable access to structural information from the atomic to the nanometer scale, directly in the laboratory. Built on Xenocs’ expertise in Small and Wide Angle X-ray Scattering (SAXS and WAXS), the Nano-inXider combines proven scattering performance with a fully automated, user-friendly design optimized for routine and high-throughput use.

Designed for everyday research environments, the Nano-inXider provides simultaneous SAXS and WAXS measurements in a single exposure, ensuring unambiguous structural insights across multiple length scales. Its compact, vertical architecture, beamstop-less acquisition, and integrated data processing make high-quality nanoscale characterization accessible to both experts and non-specialists, from academic research to industrial R&D.

Key features that set the Nano-inXider apart include

01

Accurate and high dynamic range measurements

Capture both intense and weak scattering signals with beamstop-less acquisition and Clean Beam Technology for accurate absolute data.

02

Directly from samples to results

Move seamlessly from sample loading to results with fully automated alignment, acquisition, and data processing.

03

Simultaneous data from atomic- to nano-scale

Access atomic- and nanoscale structural information simultaneously with combined SAXS/WAXS in a single exposure.

04

Low Cost of Ownership

Perform daily nanoscale characterization with a compact, energy-efficient, and low-maintenance instrument.

01

Accurate and high dynamic range measurements

The Nano-inXider delivers reliable, high signal-to-noise SAXS/WAXS data across a wide intensity range, enabling confident quantitative analysis from weakly scattering samples to large structural features. Beamstop-less acquisition combined with Xenocs’ Clean Beam Technology delivers simultaneous measurement of transmitted and scattered signals, ensuring accurate absolute intensity normalization and exceptional data reliability across the full dynamic range.

Clean Beam Technology for high dynamic range measurements

The Nano-inXider leverages 25 years of Xenocs R&D in advanced X-ray optics and instrument design to achieve an optimal balance between high X-ray flux at the sample and exceptionally low parasitic scattering generated by the instrument itself. This balance is essential for high dynamic range measurements and reliable detection of weak scattering signals.

Clean Beam Technology integrates a carefully engineered set of components designed to preserve beam quality from source to detector:

- Microfocus sealed-tube X-ray source (30 W) coupled with patented single-reflection multilayer optics for high brilliance and beam stability

- Patented motorized scatterless collimation, minimizing background and parasitic scattering

- Fully in-vacuum beam path, from optics to detector, reducing air scattering to a minimum

- Low-noise hybrid pixel photon-counting detector, ensuring accurate detection across a wide intensity range

- Windowless SAXS detector.

Beamstop-less acquisition for high-quality data

The Nano-inXider uses beamstop-less SAXS acquisition to record the transmitted direct beam and the scattered signal simultaneously, enabling high dynamic range measurements while preserving weak scattering features.

Continuous measurement of the direct beam allows automatic normalization to absolute intensity, while the absence of a beamstop eliminates parasitic edge scattering and enables clean data at low q, with automatic qmin determination adapted to each sample.

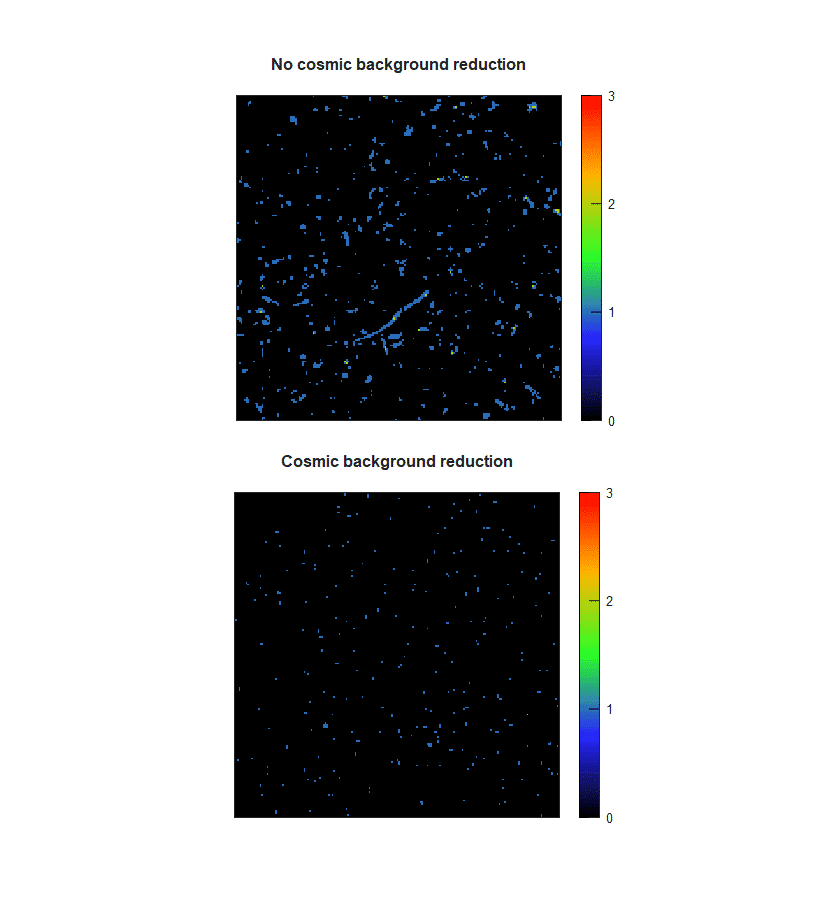

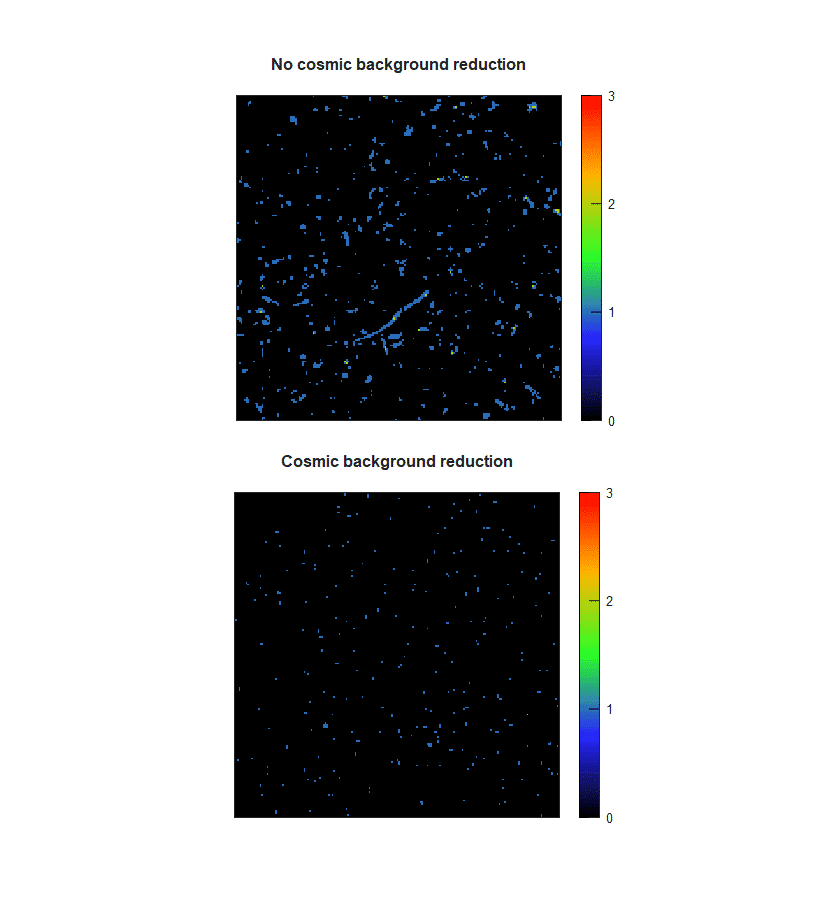

Cosmic background reduction

Automatic cosmic background removal continuously corrects for ambient parasitic radiation during data acquisition. By identifying and removing spurious events caused by cosmic rays, this feature improves signal-to-noise ratio and preserves data integrity, particularly for long acquisitions and very low-intensity scattering signals. The result is cleaner, more reliable data without user intervention.

02

Directly from samples to results:

The SMART workflow for efficient nanoscale characterization

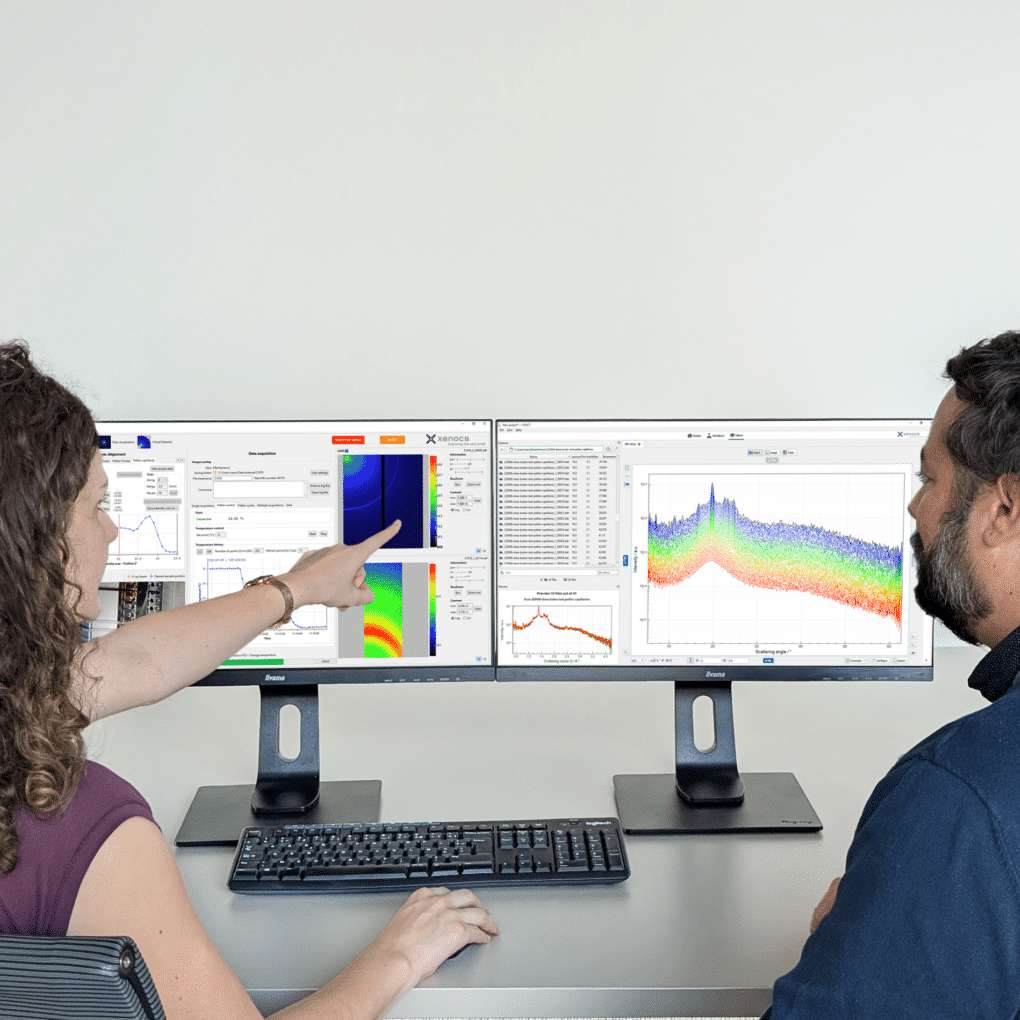

With the Nano-inXider SMART design, move seamlessly from sample loading to validated results. The entire workflow is automated, minimizing user interaction while ensuring accuracy, reproducibility, and speed.

With remote operation and automatic alignment, the Nano-inXider minimizes human error while guaranteeing measurement traceability and reproducibility.

Its ease of use and robustness make it ideally suited for multi-user and open-access laboratories.

Sample

Simply place the sample in the chamber. The instrument automatically aligns itself without any user intervention, reducing setup time and eliminating alignment errors.

Measurement

Data acquisition is fully automated and fast. Scattering data are automatically normalized to absolute intensity, with no calibration required by the user, thanks to a fully motorized instrument and a fixed dual-detector configuration controlled by an integrated software suite.

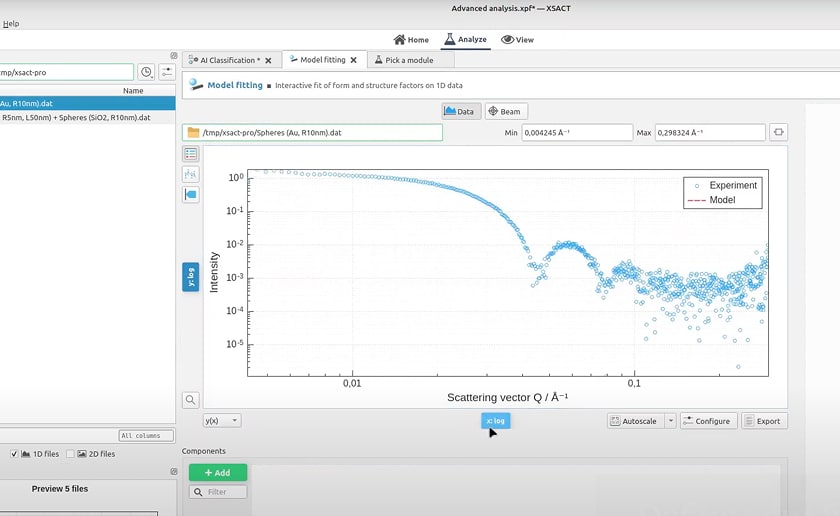

Analysis

Scattering data are displayed in real time for immediate feedback. Advanced analysis is performed using XSACT Pro software, offering a comprehensive set of algorithms and rapid access to key nanostructure parameters through an intuitive interface.

Report

Generate publication-ready figures in just a few clicks. XSACT Pro produces high-quality graphs that can be exported directly or integrated into reports and presentations via drag-and-drop.

Time-saving

Fast answers with minimal user effort. The SMART design ensures a short learning curve for scattering experts, material scientists, and technicians alike, enabling efficient daily use.

03

Simultaneous data from atomic- to nano-scale

The Nano-inXider delivers true simultaneous SAXS/WAXS measurements, capturing atomic- and nanoscale structural information in a single exposure. Its integrated dual-detector design provides a coherent, multi-scale view of sample structure, ensuring reliable interpretation across length scales.

To access large characteristic dimensions without compromising laboratory space, the Nano-inXider combines a long SAXS sample-to-detector distance with a unique compact vertical architecture. This design extends q-range coverage while maintaining a minimal footprint, making advanced multi-scale characterization readily accessible directly in the lab.

Fixed dual detector design

With the Nano-inXider, SAXS and WAXS data are acquired simultaneously in a single exposure, with both the sample and detectors remaining fixed throughout the experiment. The integrated WAXS detector seamlessly extends the scattering range beyond SAXS, providing continuous coverage up to \(2θ=60°\) with intrinsic overlap between datasets.

This unique vertical fixed-geometry design, unmatched by any other laboratory SAXS system on the market, delivers decisive advantages:

- True simultaneous SAXS/WAXS acquisition, providing unambiguous multi-scale structural information, from atomic to nanoscale, in a single measurement on the same sample volume, with seamless q-range overlap for reliable data merging and intensity scaling

- A fixed, optimized vertical geometry, delivering effortless operation, long-term stability, and highly reproducible results

- Reliable in situ and operando studies, where structural evolution must be tracked simultaneously at atomic and nanoscale

By combining true simultaneous SAXS/WAXS acquisition with a unique fixed vertical geometry, the Nano-inXider sets a new benchmark for coherent, multi-scale structural characterization directly in the laboratory.

Virtual detector for increased azimuthal coverage

For anisotropic samples such as fibers or oriented films, the Nano-inXider employs an automated sample rotation stage to acquire scattering data over a wide range of orientations. This virtual detector approach significantly extends azimuthal coverage without increasing experimental complexity.

The acquisition workflow is fully automated and includes:

- Controlled rotation of the sample around the X-ray beam during sequential exposures

- Automatic merging of the acquired scattering patterns

- Reconstruction of a final 2D scattering image with azimuthal coverage exceeding 200° across the full instrument q-range (up to 2θ=60°)

This approach enables accurate analysis of orientation and anisotropy while preserving data quality and experimental simplicity.

04

Low cost of ownership

The Nano-inXider is designed to integrate easily into standard laboratory environments while keeping installation, operation, and maintenance costs to a minimum.

Services

Specifications

Source and optics

- Microfocus sealed tube: Cu, 30W/30µm*, point focus. (* DIN EN 12543-5).

- Patented 2D single reflection multilayer optics.

Detector

- Two fixed detectors for continuously and simultaneously.

- Dectris Pilatus 3 hybrid photon counting detectors.

- SAXS and WAXS acquisition up to 2θ=60°.

Beam Path

- Windowless beam path entirely under vacuum from beam delivery system to detector sensor.

Key features

- Clean Beam technology: high flux and low background beamline.

- Beamstopless measurement: SAXS acquisition continuously without any beamstop.

- Virtual detector mode: > 200° azimuth coverage with rotation of sample.

Measurement capability

- Nanoparticles size up to 250 nm in diameter.

Sample environment

- Standard holders: solids, capillaries, powders.

- Sample holders for powders and gels.

- Flow cells for liquids:

— Low noise flow cell

— Capillary flow cell - Automatic Sample Changer

- Temperature stages:

— Multi-purpose X-Ray Temperature Stage (-20°C to 150°C)

— High temperature sample stage (-150°C to 350°C)

— Extended high temperature sample stage (amb – 700°C) - Tensile Stage (0-200N).

- GiSAXS stage compatible with high temperature sample stage.

- Custom stages on request.

Software

Comprehensive Software Suite:

- Acquisition software with automatic data reduction in absolute units and live data display.

- XSACT Pro (X-ray Scattering Analysis and Calculation Tool) for data analysis and interpretation, including unique modules for particle shape determination through direct modeling or AI-powered classification.

General parameters

- Fooprint: < 1×1 m².

- Weight: ~ 520 kg.

- Maximum power consumption: < 2000 W (single phase power).

- Self-contained: no external fluids required.