Temperature-Induced Structural Evolution by SAXS/WAXS

Temperature profoundly influences nanoscale organization in polymers, soft matter, colloids, and functional materials. Heating, cooling, or thermal cycling can trigger phase transitions, modify domain spacing, alter crystalline order, or initiate structural rearrangements that directly affect mechanical, optical, and electronic properties.

Small-Angle and Wide-Angle X-ray Scattering (SAXS/WAXS) provide a direct, non-destructive way to follow these transformations in situ. Because SAXS and WAXS probe complementary length scales, they reveal how thermal conditions reshape materials from the atomic lattice to the mesostructure.

What is measured?

Temperature-controlled SAXS/WAXS experiments capture how structure evolves as thermal energy drives reorganization. From scattering data, one can extract:

- Thermal phase transitions, including crystallization, melting, order–order transitions, or disordering

- Changes in characteristic spacing (lamellar period, domain spacing, correlation lengths)

- Crystallinity evolution, via WAXS peak intensity, position, and width

- Thermal hysteresis, offering insight into reversible versus irreversible pathways

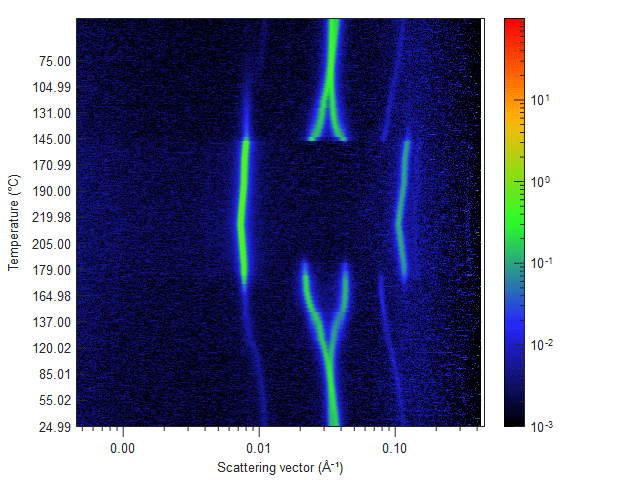

Figure 1. Thermal hysteresis in an organic photovoltaic donor material

SAXS/WAXS measurements on a dithienocyclopenta-thieno[3,2-b]thiophene (DTCTT)–based small-molecule donor reveal clear hysteresis during heating–cooling cycles. Changes in scattering patterns highlight the interplay between molecular packing and mesoscale ordering as temperature varies. See Y. Abe et al., Unique Reversible Crystal-to-Crystal Phase Transition—Structural and Functional Properties of Fused Ladder Thienoarenes, Chem. Mater. 29.18, (2017). DOI: 10.1021/acs.chemmater.7b0122

These measurements allow researchers to map complete thermal trajectories and understand how nanoscale structure governs macroscopic performance.

Samples

Temperature-induced structural evolution can be studied in an exceptionally wide range of materials, including:

- Semi-crystalline and engineering polymers undergoing melting, crystallization, or thermal reorganization

- Block copolymers, micelles, surfactants, and self-assembled soft-matter systems

- Organic semiconductors and thin films undergoing annealing or order–disorder transitions

- Colloidal, nanoparticle, and hybrid inorganic–organic assemblies sensitive to thermal history

- Biomolecular materials, such as protein complexes, lipid assemblies, or biopolymer networks

- Energy materials, including battery electrodes, solid electrolytes, and catalytic nanostructures

- Pharmaceutical formulations, where temperature affects aggregation or polymorphism

- Food and cosmetic formulations, including emulsions, gels, and structured soft materials

- Nanostructured or porous materials, whose periodicity or crystallinity changes with temperature

Both heating and cooling modes allow detailed mapping of reversible and irreversible phenomena.

Why use SAXS/WAXS for Temperature-Induced Structural Evolution analysis?

Temperature-controlled SAXS/WAXS provides a unique window into how materials reorganize across multiple length scales when heated or cooled.

Direct access to temperature-driven structural evolution

Allowing detection of nanoscale rearrangements, domain changes, and phase transitions as they occur.

Complementary insight across length scales

Combining SAXS sensitivity to mesoscale periodicities with WAXS access to crystalline order for a unified picture of thermal response.

Quantitative measurement of temperature-dependent parameters

Enabling precise tracking of spacing, crystallinity, correlation lengths, and ordering throughout heating or cooling cycles.

Continuous, non-destructive in situ monitoring

Capturing reversible and irreversible transformations without removing, altering, or interrupting the sample.

Compatibility with a broad temperature range

Supporting cryogenic, ambient, and high-temperature conditions while maintaining stable measurement geometry and data quality