Nanoparticle and Pore Size and Size Distribution by SAXS

Controlling nanoparticle size and size distribution is essential across fields such as materials science, chemistry, biotechnology, and energy research. Indeed, these parameters govern key properties, from optical and mechanical behavior to catalytic activity, stability, and overall performance.

Small-Angle X-ray Scattering (SAXS) provides a non-destructive and statistically robust way to determine particle size distributions directly from the scattering intensity profile, without the need for dilution, labeling, or extensive sample preparation.

What is measured?

Small-Angle X-ray Scattering (SAXS) measures how X-rays are deflected at very small angles by nanoscale variations in electron density within a material. By analyzing the shape and intensity of the scattering curve, researchers can reconstruct how matter organizes on the nanometer scale. This reveals the size, shape, and distribution of nanoparticles, as well as the dimensions of pores or voids in porous materials.

When calibrated in absolute intensity units, SAXS data can be used to extract quantitative physical parameters, including:

- Average particle or pore diameter, reflecting the characteristic size of the scatterers or voids

- Number- or volume-weighted size distribution, providing insight into polydispersity

- Volume fraction or mass concentration, obtained from absolute intensity normalization

Moreover, by integrating the signal from the entire particle or pore ensemble, SAXS provides statistically robust results. Consequently, the measurements represent the full sample rather than a limited subset.

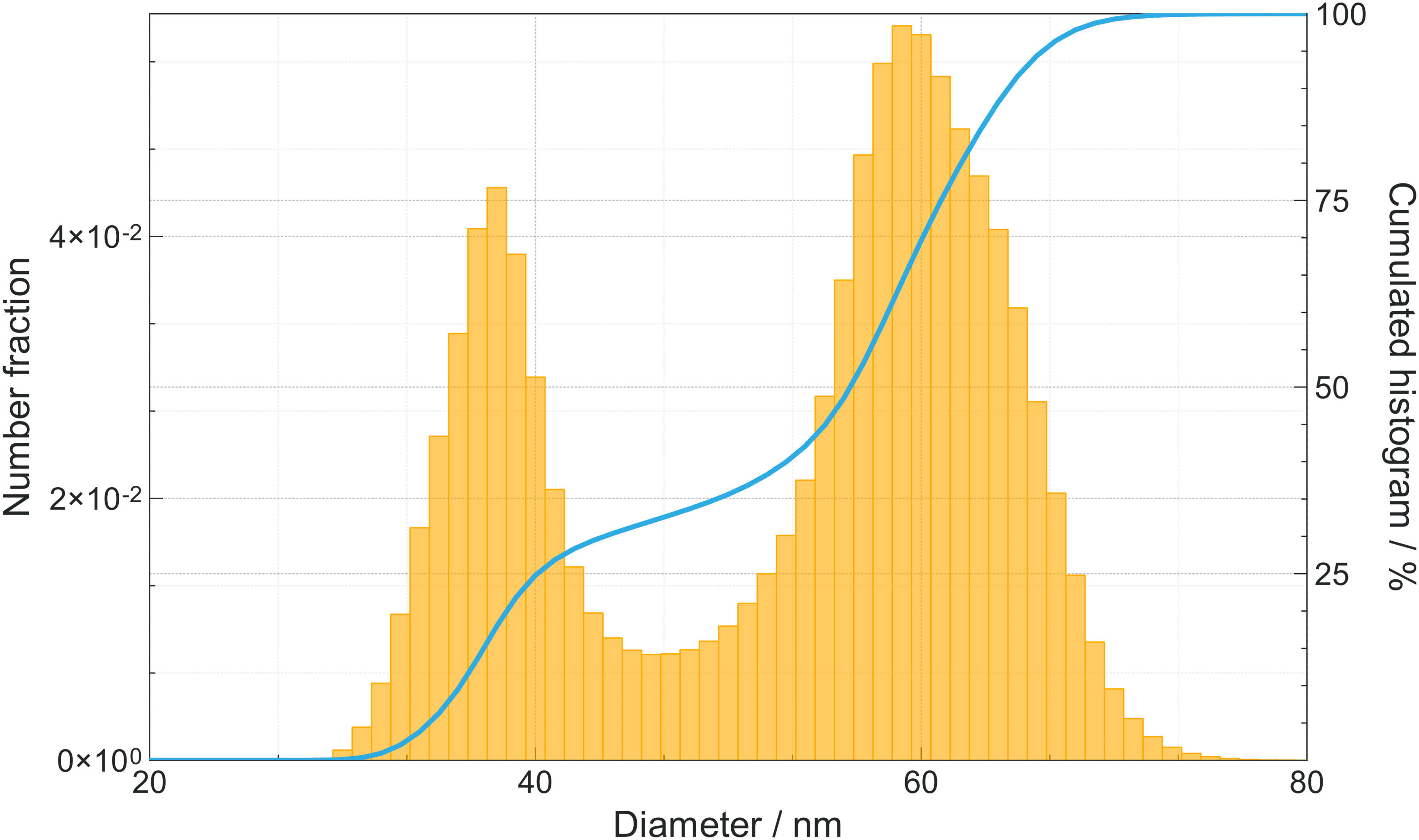

Figure 1. SAXS-derived size distributions for a bimodal mixture of 40 nm and 60 nm gold nanoparticles (30:70 ratio), measured on the Nano-inXider and analyzed with XSACT Pro.

Modern laboratory instruments can determine particle or pore sizes sizes ranging from approximately 1 to 900 nanometers with high precision with high precision. In addition, when equipped with a USAXS (Ultra-SAXS) extension, the accessible range extends up to several micrometers. Therefore, this enables the study of multimodal or hierarchical systems, including aggregation or agglomeration phenomena that often occur during synthesis, storage, or processing.

Samples

SAXS can be applied to a broad variety of materials, from liquids and soft matter to solids and complex functional devices. Moreover, the technique is non-destructive, requires only a small quantity of sample, and accommodates many different physical forms without extensive sample preparation.

Because X-rays penetrate deeply into matter, researchers can directly analyze even opaque suspensions or dense powders. Thus, this versatility enables the study of:

- Liquids and dispersions – colloids, emulsions, nanofluids

- Dry powders – metallic, ceramic, or organic nanoparticles

- Gels and pastes – hydrated or concentrated systems

- Porous or solid nanostructures – catalysts, coatings, nanocomposites, and battery or energy storage materials

Additionally, SAXS measurements can also be performed in situ or operando. This provides insight into particle growth, aggregation, phase transitions, or structural evolution under realistic conditions such as temperature, humidity, flow, or electrochemical cycling. This capability makes SAXS an essential tool for understanding how nanostructure changes during synthesis and operation, linking structural dynamics directly to material performance.

Why use SAXS for Nanoparticle and Pore Size and Size Distribution determination?

SAXS combines precision, representativeness, and versatility in a single measurement technique. It provides quantitative structural information across a wide size range, typically from one nanometer up to several micrometers, without altering or damaging the sample.

Exceptional structural resolution

Allowing accurate determination of small nanoparticles and complex, multimodal or hierarchical size distributions.

Statistically robust results

Obtained through ensemble averaging over millions of particles or pores.

Minimal sample preparation

Enabling measurements on powders, opaque suspensions, gels, or solid materials without dilution or complex treatment.

Sensitivity to both open and closed pores

As SAXS detects any internal contrast in electron density, providing a complete view of total porosity.

In situ and operando capabilities

Enabling the observation of particle growth, aggregation, or pore evolution under real synthesis, processing, or operating conditions.

Overall, through these combined features, SAXS delivers a comprehensive understanding of how nanoscale architecture influences material performance, from catalysts and polymers to batteries, membranes, and biological assemblies.