Lamellar Structure by SAXS

Lamellar organization is a defining structural motif in many semi-crystalline polymers. Indeed, the alternating arrangement of crystalline and amorphous layers governs essential material properties such as mechanical strength, barrier performance, melting behavior, and optical response. Understanding the lamellar spacing, long period, and crystalline layer thickness is therefore fundamental to optimizing polymer processing conditions and predicting end-use performance.

Small-Angle X-ray Scattering (SAXS) provides a non-destructive and quantitative method to characterize these lamellar structures directly in bulk materials, thin films, or processed components, without staining, sectioning, or complex preparation.

What is measured?

SAXS probes X-rays scattered by electron density contrasts between the crystalline and amorphous layers that form the lamellar stacks in semi-crystalline polymers. The resulting scattering pattern typically exhibits sharp long-period peaks or oscillations that reflect the periodicity of these alternating domains.

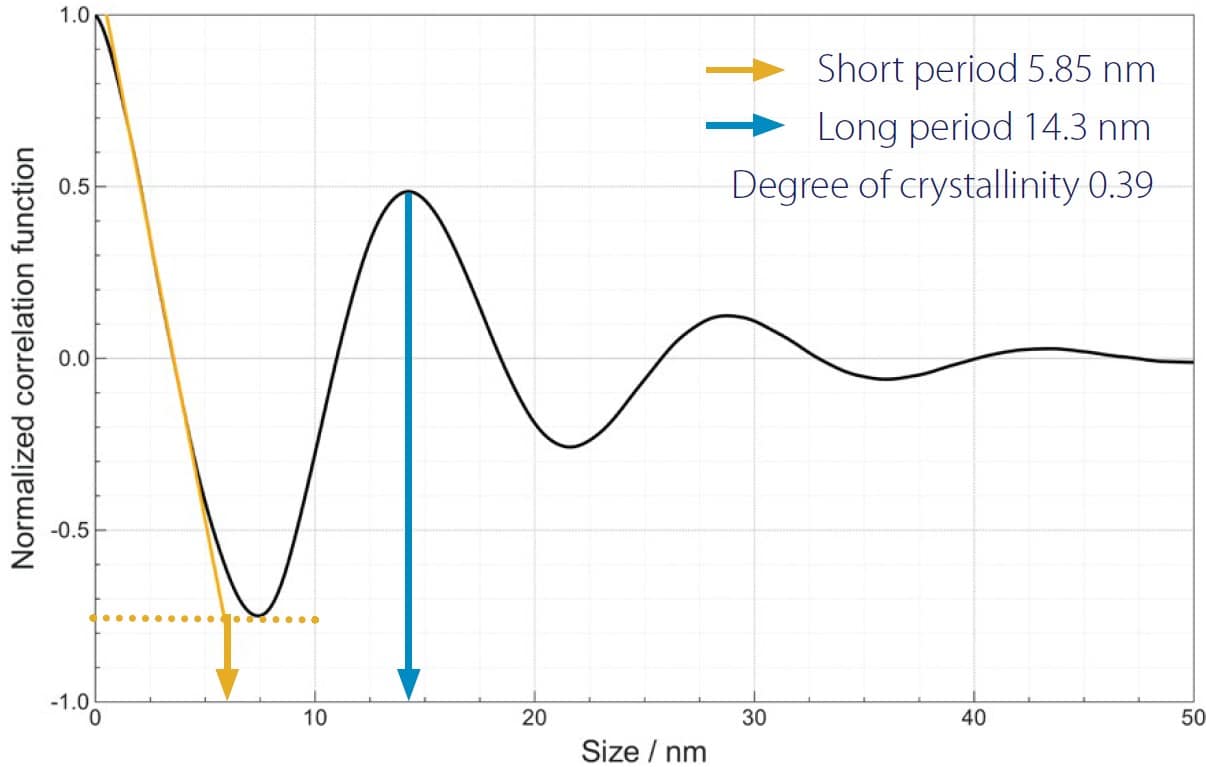

Furthermore, when data are analyzed in real space using the electron density auto-correlation function, SAXS provides access to quantitative lamellar parameters [1], including:

- Long period (L), corresponding to the average repeat distance of the lamellar stack

- Crystalline layer thickness, related to the crystalline domain within each period

- Amorphous layer thickness, obtained from the full periodic profile

Figure 1. Auto-correlation function extracted from SAXS data of a semi-crystalline polymer, illustrating the long and short periods associated with the lamellar stack (processed with the XSACT Pro software).

Because SAXS integrates the signal from large material volumes, the resulting parameters represent statistically meaningful, bulk-averaged structural information, highly relevant for polymers where morphology depends sensitively on processing history.

[1] G.R. Strobl, M.J. Schneider and IG.G. Voigt-Martin, Journal of Polymer Science, 18, 1361-1381, (1980). DOI: 10.1002/pol.1980.180180615

Samples

Lamellar spacing analysis by SAXS applies to a broad variety of semi-crystalline and self-assembled polymer systems.

Typical materials include:

- Semi-crystalline polymers such as PE, PP, PA, PEEK, PEKK, PET, and bio-based polymers

- Block copolymers exhibiting lamellar microphase separation

- Polymer blends and nanocomposites where lamellae form or reorganize during processing

- Films, fibers, molded components, or powder materials

- Samples under processing conditions, including heating, cooling, stretching, or flow

Moreover, because SAXS is non-destructive and requires little to no preparation, lamellar structures can be studied in situ, following crystallization, melting, annealing, cold-crystallization, or structural rearrangement in real time.

Why use SAXS for Lamellar Structure characterization?

SAXS provides a direct, quantitative view of the layered organization that defines semi-crystalline polymer morphology. Its strengths include:

Direct access to lamellar organization

Probing the periodic alternation of crystalline and amorphous layers through intrinsic electron density contrast.

Quantitative determination of lamellar parameters

Including long period, crystalline and amorphous thicknesses.

Minimal sample preparation

Wnabling measurements on bulk polymers, films, fibers, or molded components without staining, sectioning, or microtoming.

Non-destructive probing

Preserving the polymer morphology and allowing repeated or comparative measurements

Sensitivity to subtle structural changes

Detecting lamellar thickening, recrystallization, or morphological evolution during thermal or mechanical treatment.

In situ and operando capabilities

Enabling real-time monitoring of crystallization kinetics, melting, annealing, or mechanical deformation.

Together, these features make SAXS an essential tool for linking polymer processing conditions, lamellar morphology, and final material performance.