Crystalline Fraction by WAXS

Crystallinity is a key structural parameter in semi-crystalline polymers. Indeed, the balance between crystalline and amorphous domains directly influences mechanical strength, thermal stability, dimensional behavior, or optical properties. Accurate quantification of the crystalline fraction is therefore essential for understanding polymer performance and optimizing processing conditions.

Wide-Angle X-ray Scattering (WAXS) provides a direct and non-destructive approach to determine the crystalline fraction of polymer materials. By analyzing the characteristic Bragg peaks of the crystalline phase and the diffuse scattering of the amorphous component, WAXS yields a quantitative and statistically representative measure of crystallinity without the need for staining, sectioning, or thermal protocols.

What is measured?

WAXS probes X-rays scattered at wide angles by regular atomic arrangements in crystalline domains. In particular, in semi-crystalline polymers, the scattering pattern contains:

- Sharp crystalline peaks, arising from the ordered lattice

- Broad amorphous scattering, originating from disordered regions

By separating these contributions, it is possible to determine the fraction of crystalline material within the polymer.

Typical measurable parameters include:

- Crystalline fraction, based on integrated intensities of crystalline and amorphous contributions

- Relative fractions of different crystalline phases, when multiple polymorphs are present (e.g., alpha vs. gamma)

- Lattice spacing and crystalline domain characteristics, inferred from the position and width of the WAXS peaks

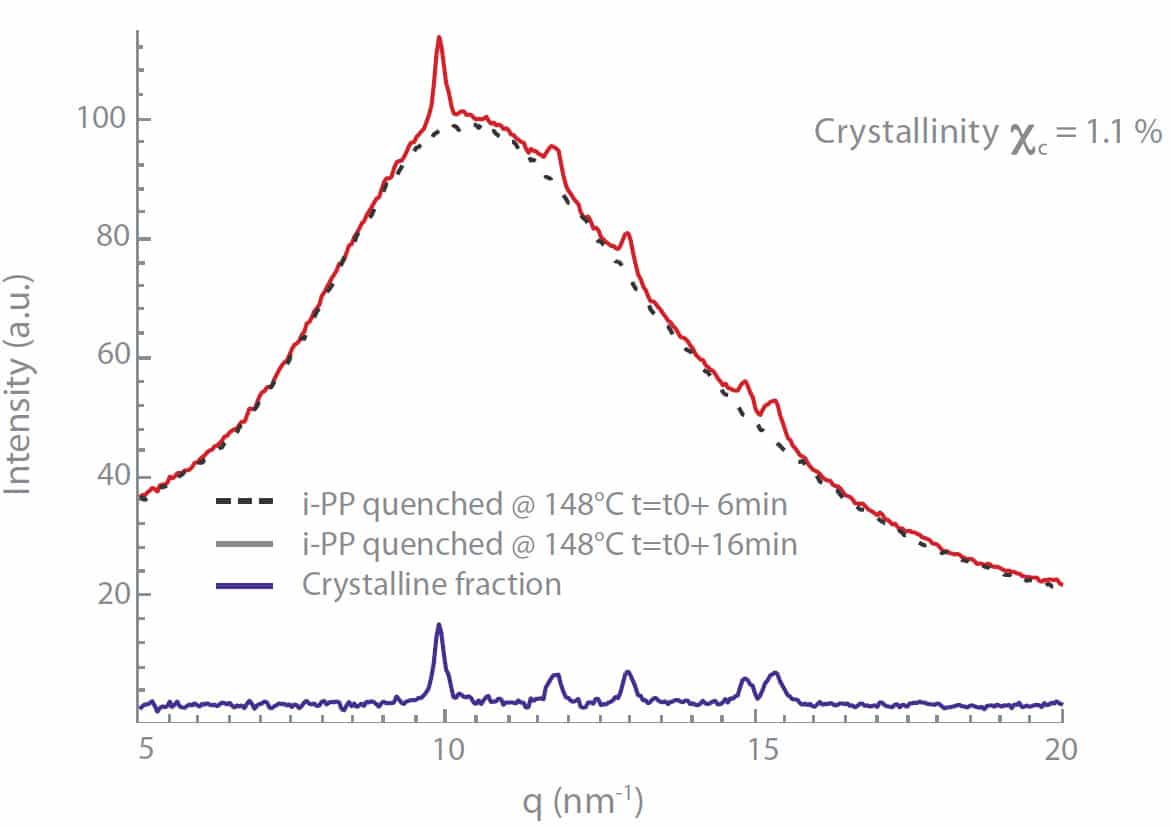

Figure 1. Crystallinity determination from experimental data using subtraction of the amorphous contribution (dashed line), revealing a crystalline fraction of 1.1%.

Moreover, laboratory WAXS instruments can quantify crystalline fractions from approximately 1% to 90%, with sensitivity extendable down to ~0.2% when accurate amorphous references or thermal protocols are available.

Samples

Crystallinity determination by WAXS applies to any polymer system exhibiting meaningful electron density contrast between crystalline and amorphous phases.

For example, typical materials include:

- Polyolefins such as PE, PP, and their copolymers

- High-performance polymers such as PEEK, PEKK, and related semi-crystalline engineering plastics

- Polymer blends, composites, and filled systems

- Films, fibers, molded components, or powders

- Materials under thermal or mechanical treatment, including crystallization, melting, or annealing processes

Because the technique is non-destructive and requires minimal preparation, measurements can be performed on bulk samples, thin sections, or processed parts, as well as in situ under controlled temperature or environmental conditions.

Why use WAXS for Crystalline Fraction determination?

WAXS offers a robust, quantitative, and laboratory-accessible method for determining polymer crystallinity. Its advantages include:

Direct structural sensitivity

Distinguishing crystalline and amorphous contributions based on their intrinsic scattering signatures.

Quantitative crystallinity determination

Enabling absolute fraction calculation independent of thermal analysis and free from baseline assumptions.

Capability to resolve multiple crystalline phases

Supporting phase-specific crystallinity analysis in polymorphic polymers.

Minimal sample preparation

Allowing measurements on bulk materials and processed components without staining, cutting, or thermal conditioning.

Statistically representative results

Derived from scattering volumes on the order of cubic millimeters.

In situ and operando compatibility

Enabling real-time monitoring of crystallization, melting, recrystallization, and phase transitions

These capabilities make WAXS an indispensable tool for linking polymer processing, crystalline morphology, and functional performance.