Orientation Analysis by SAXS/WAXS

The orientation of nanoscale structures plays a central role in determining the properties of many materials. In polymers, fibers, liquid crystals, and engineered nanostructures, the direction and degree of alignment influence mechanical strength, transport properties, optical anisotropy, and performance under processing conditions.

Small-Angle and Wide-Angle X-ray Scattering (SAXS/WAXS) provide a direct, non-destructive method to quantify nanostructural and molecular orientation. By measuring how scattering intensity varies as a function of azimuthal angle around a selected Bragg reflection, SAXS/WAXS reveals both the preferred orientation direction and its distribution.

What is measured?

SAXS and WAXS probe the anisotropy of scattering intensities in reciprocal space. When nanoscale features or crystalline domains are preferentially aligned, their scattering becomes direction-dependent, producing characteristic azimuthal modulations.

From these patterns, SAXS/WAXS enables quantitative extraction of:

- Mean orientation direction, defining how the structural motif (e.g., lamellae, fibrils, crystallites) aligns with respect to a sample reference frame

- Degree of orientation, based on the sharpness or spread of the azimuthal intensity distribution

- Orientation distribution functions, derived using tensor-based models [1] or moment analysis

- Orientation metrics such as Herman’s orientation factor, providing a single-valued descriptor of alignment [2]

These parameters can be computed from specific reflections in WAXS (e.g., crystal lattice planes) or from structural features observed in SAXS (e.g., lamellar stacks, fibrillar scattering).

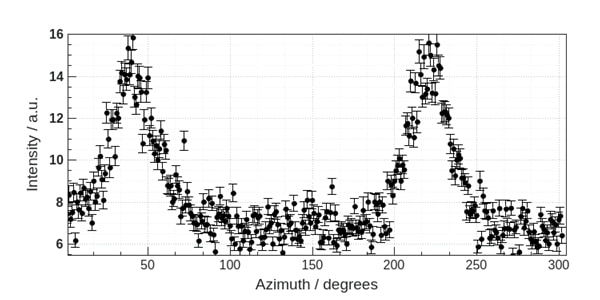

Figure 1. Azimuthal profile of the q = 0.27 nm-1 Bragg reflection of a high density polyethylene. The mean orientation is found at 39.9° for a rate of 17% oriented scatterers.

[1] D. K. Cinader, W. R. Burghardt, X-ray scattering studies of orientation in channel flows of a lyotropic liquid crystalline polymer, Polymer 40.15, (1999), DOI: 10.1016/S0032-3861(98)00667-3

[2] J.J. Hermans, P.H. Hermans, D. Vermaas, A. Weidinger, Quantitative evaluation of orientation in cellulose fibers from the X-ray fiber diagram, Recl. Trav. Chim. Pays- Bas 65 (1946), DOI: 10.1002/recl.19460650605

Samples

Orientation analysis by SAXS/WAXS applies to materials where structural alignment occurs at nanometer or molecular length scales.

Typical systems include:

- Textured polymers and semi-crystalline materials

- Fibers and filaments, including polymer, cellulose, or composite fibers

- Liquid-crystalline materials, in bulk or thin films

- Nanostructured composites and templated materials

- Materials processed under flow, shear, stretching, or extrusion

SAXS/WAXS measurements can be conducted on bulk specimens, thin films, pellets, fibers, or in situ during processing or mechanical deformation.

Why use SAXS/WAXS for Orientation Analysis?

SAXS and WAXS offer unique advantages for quantifying nanoscale orientation:

Direct structural sensitivity

Capturing real-space alignment through the anisotropy of reciprocal-space scattering.

Non-destructive analysis

Allowing measurements on intact samples without sectioning, staining, or microscopy preparation.

Full-volume representativeness

Because the X-ray beam probes the entire illuminated sample volume rather than only a surface layer.

Minimal sample preparation

Enabling measurements on bulk materials, fibers, films, or mechanically processed specimens.

In situ and operando capabilities

Supporting real-time monitoring of orientation during stretching, flow, heating, or cooling.

Compatibility with both ordered and semi-ordered systems

Enabling orientation analysis of crystalline domains as well as nanostructured assemblies.

Together, these capabilities make SAXS/WAXS essential tools for understanding how processing, deformation, and self-assembly produce anisotropic structures, and how these structures govern material performance.