Specific Surface Area by SAXS

The specific surface area of a material, the interfacial area per unit mass or volume, is a key parameter that governs reactivity, adsorption capacity, catalytic performance, dissolution behavior, and mechanical properties. In systems such as nanoparticles, porous solids, emulsions, or granular media, the total accessible or internal surface area strongly influences functionality.

Small-Angle X-ray Scattering (SAXS) provides a direct and quantitative route to determine specific surface area across a wide range of materials. In particular, by analyzing how intensity decays at high scattering vectors, SAXS extracts the surface-to-volume ratio even when surfaces are buried, inaccessible, or present as closed pores, without altering or damaging the sample.

What is measured?

SAXS measures the scattering arising from electron-density contrast between two phases. For biphasic systems (e.g., particles in solution, pores within solids), the high-q region of the scattering curve carries information about the total interfacial area between the phases.

From this analysis, SAXS provides:

- Specific surface area, expressed as interfacial area per unit mass (m²/g) or per unit volume (m²/cm³)

- Surface-to-volume ratio, derived from the Porod regime intensity decay

- Total scattering invariant, used to normalize the interfacial area and ensure quantitative accuracy

- Access to both open and closed pores, because the contrast-based signal originates from all interfaces, not only externally accessible ones

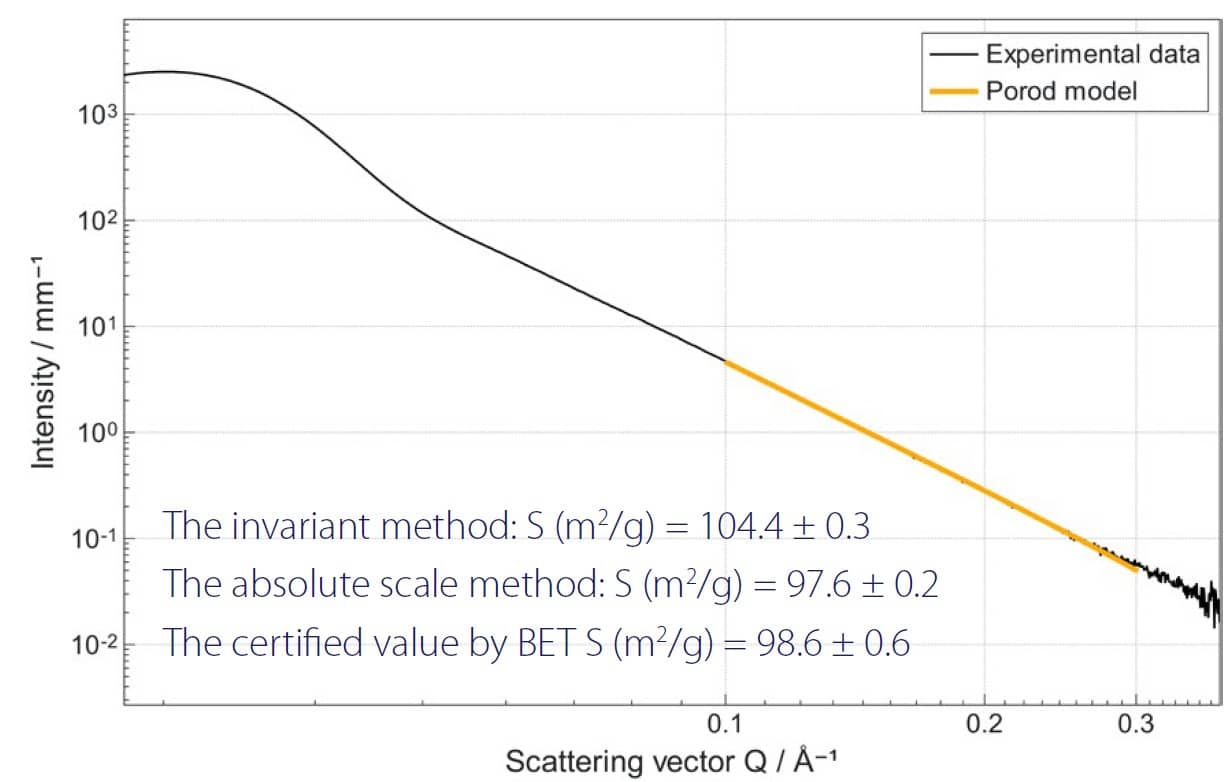

Figure 1. Specific surface area determination of SiO₂ using SAXS.

The Porod region of the scattering curve (yellow) is used to extract the surface-to-volume ratio and evaluate the total scattering invariant, enabling quantitative determination of the specific surface area. The SAXS-derived values show excellent agreement with the certified BET reference for this SiO₂ sample, demonstrating the accuracy of SAXS for surface-area analysis.

Specific surface determination typically relies on Porod analysis, which relates the slope of the high-q scattering to surface area, combined with accurate extrapolation of the data and normalization via the scattering invariant.

In addition, these approaches follow the methodologies formalized in ISO 20804:2022, the international standard governing SAXS determination of specific surface area in porous and particulate materials.

Samples

SAXS enables specific surface determination for a wide variety of two-phase materials, including:

- Colloidal dispersions and solutions, such as nanoparticle suspensions

- Dry powders and particulate materials

- Porous solids, including mesoporous or microporous media

- Granular or composite materials

- Nanostructured solids, such as catalysts or templated materials

Because SAXS requires minimal preparation and probes large sample volumes, it is ideally suited for native, undisturbed samples, including opaque or dense materials.

Why use SAXS for Specific Surface Area determination?

SAXS provides a robust, quantitative, and broadly applicable method for measuring interfacial area. Its strengths include:

Access to closed and internal pores

Since SAXS detects all electron-density interfaces, not only accessible surfaces.

Absolute intensity capability

Enabling direct surface area quantification without empirical calibration.

Non-destructive analysis

Preserving delicate structures and allowing repeated or comparative measurements.

Compatibility with liquids, gels, powders, and solids

Requiring little to no sample preparation.

Applicability across temperature and environmental conditions

Enabling in situ studies during drying, heating, or processing.

These advantages make SAXS a powerful technique for understanding how nanoscale interfacial structure influences material performance, from catalysts and porous media to nanoparticles, composites, and energy-storage materials.